Horizontal Chocolate Bar /Granola Bar Packaging Machine

Features

This granola bar packaging machine is a very strong packaging capacity and can be suitable for a variety of specifications of continuous packaging machines. The chocolate bar packaging machine can not only be used for chocolate bar and granola bar, but also candy bar, protein bar, energy bar, snack bar, cereal bar, etc.

Horizontal Granola Bar Packaging Machine Features:

〇 Use two inverter control (higher precision can use three servo control), the bag length can be adjusted, saving time and saving film.

〇 The chocolate bar packaging machine uses man-machine interface, temperature, speed and other parameters clearly visible, easy control.

〇 Photoelectric eye tracking with high sensitivity makes the sealing and cutting position more accurate. Photoelectric switch is also equipped above the conveying film to detect whether the film is in place.

〇 Horizontal and vertical seals are controlled by independent temperature controller, convenient for users to adjust the temperature when high-speed packaging.

〇 Simple transmission system, more reliable work, more convenient maintenance.

〇 The chocolate bar packaging machine can be equipped with nitrogen (suitable for food), automatic coding (ink coding, heat transfer printing), punching, pinhole exhaust device can be customized according to customer requirements.

〇 The automatic feeding machine can be connected to the energy bar packaging machine to realize the unmanned packaging of the entire production line, save labor and cost, and improve product competitiveness.

Cereal Bar Packaging Machine Advantages:

High efficiency: The entire cereal bar packaging system enables gentle product handling and smooth transfer, reducing downtime and improving packaging efficiency. Packing of 40-230 cereal bars per minute can be achieved with different configurations.

Gentle handling: Gentle handling minimizes breakage during cereal bar packaging and improves yield.

Sustainable: Advanced technology makes the packaging machine suitable for packaging films of different materials.

Multifunction: The machine can adapt to the automatic production needs of the factory, and be used in connection with the production line, cartoning machine and other equipment.

Granola Bar Packaging Machine Working Process:

1. Manually place the granola/chocolate bar on the feeding device (if there is an automatic feeding machine, the chocolate bar can be automatically transported to the feeding end).

2. The film transport device automatically transports packaging film.

3. When the packaging film passes through the bag maker, the bag maker makes the packaging film into a bag.

4. When the formed bag passes through the longitudinal sealing device, the longitudinal sealing mechanism seals the back of the bag.

5. After the back of the bag, through the transverse sealing cutting device, the bag is sealed, the packaged bag automatically output.

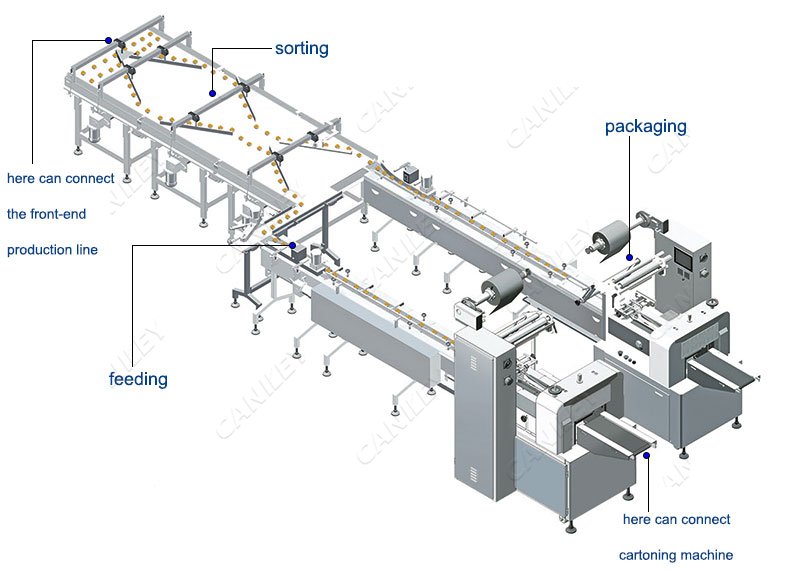

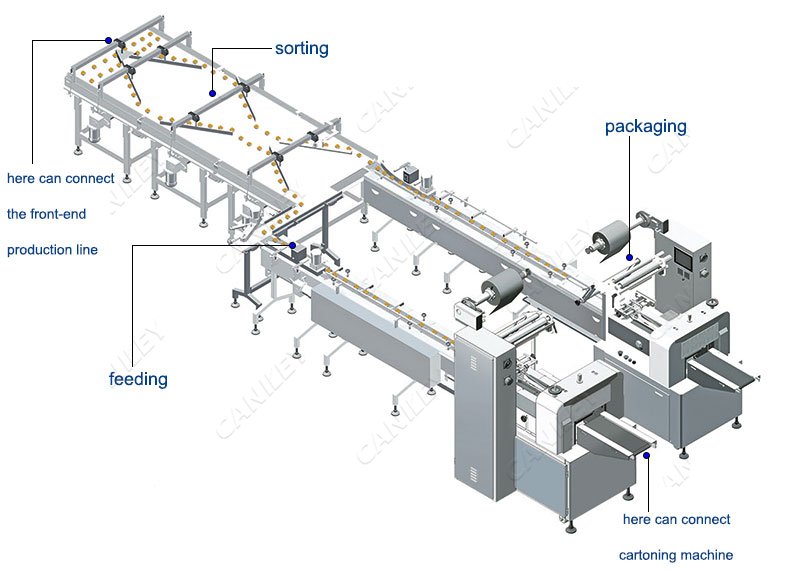

Customized Design for Bar Packaging System:

We make a customized packaging system for wrapping a different kind of bar shape food, according to the food features, packing requirements, etc. Include sorting part, feeding part wrapping part, coding part, cartooning part, etc.

Horizontal Granola Bar Packaging Machine Features:

〇 Use two inverter control (higher precision can use three servo control), the bag length can be adjusted, saving time and saving film.

〇 The chocolate bar packaging machine uses man-machine interface, temperature, speed and other parameters clearly visible, easy control.

〇 Photoelectric eye tracking with high sensitivity makes the sealing and cutting position more accurate. Photoelectric switch is also equipped above the conveying film to detect whether the film is in place.

〇 Horizontal and vertical seals are controlled by independent temperature controller, convenient for users to adjust the temperature when high-speed packaging.

〇 Simple transmission system, more reliable work, more convenient maintenance.

〇 The chocolate bar packaging machine can be equipped with nitrogen (suitable for food), automatic coding (ink coding, heat transfer printing), punching, pinhole exhaust device can be customized according to customer requirements.

〇 The automatic feeding machine can be connected to the energy bar packaging machine to realize the unmanned packaging of the entire production line, save labor and cost, and improve product competitiveness.

Cereal Bar Packaging Machine Advantages:

High efficiency: The entire cereal bar packaging system enables gentle product handling and smooth transfer, reducing downtime and improving packaging efficiency. Packing of 40-230 cereal bars per minute can be achieved with different configurations.

Gentle handling: Gentle handling minimizes breakage during cereal bar packaging and improves yield.

Sustainable: Advanced technology makes the packaging machine suitable for packaging films of different materials.

Multifunction: The machine can adapt to the automatic production needs of the factory, and be used in connection with the production line, cartoning machine and other equipment.

Granola Bar Packaging Machine Working Process:

1. Manually place the granola/chocolate bar on the feeding device (if there is an automatic feeding machine, the chocolate bar can be automatically transported to the feeding end).

2. The film transport device automatically transports packaging film.

3. When the packaging film passes through the bag maker, the bag maker makes the packaging film into a bag.

4. When the formed bag passes through the longitudinal sealing device, the longitudinal sealing mechanism seals the back of the bag.

5. After the back of the bag, through the transverse sealing cutting device, the bag is sealed, the packaged bag automatically output.

Customized Design for Bar Packaging System:

We make a customized packaging system for wrapping a different kind of bar shape food, according to the food features, packing requirements, etc. Include sorting part, feeding part wrapping part, coding part, cartooning part, etc.

Technical Data

| Type | CK-ZS320 |

| Film width | Max. 320mm |

| Bag length | 65-190 mm or 120-280mm |

| Bag width | 50-160mm |

| Product height | Max.45mm |

| Film roll diameter | Max. 320mm |

| Packaging rate | 40-230 bag/min |

| Power | 220V,50/60HZ,2.6KVA |

| Machine size | (L)3770X(W)720X(H)1450 |

| Machine quality | 900kg |

| Application | chocolate bar, granola bar, cereal bar, protein bar, etc |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price