Automatic Fruit Jam Pulp Filling Machine 4 Heads

Features

The fruit pulp filling machine can realize the route from the processing, transportation, assembly and inspection of the fruit pulp into the packaging equipment. This filling machine is suitable for all kinds of fruit pulp and jam.

Fruit Pulp Filling Machine Working Flow:

a. The bottles from the outlet of the unscrambler are automatically aligned to the same level, and then the bottle enters the aseptic filling machine.

b. There is a bottle quantity detection system on the automatic jam filling machine. When the number of bottles on the bottle feeding track reaches the preset position, the filling machine automatically starts running and completes the filling.

c. The bottle that has been filled will enter the capping machine through the conveyor track to complete the sealing process.

Automatic Jam Filling Machine Features:

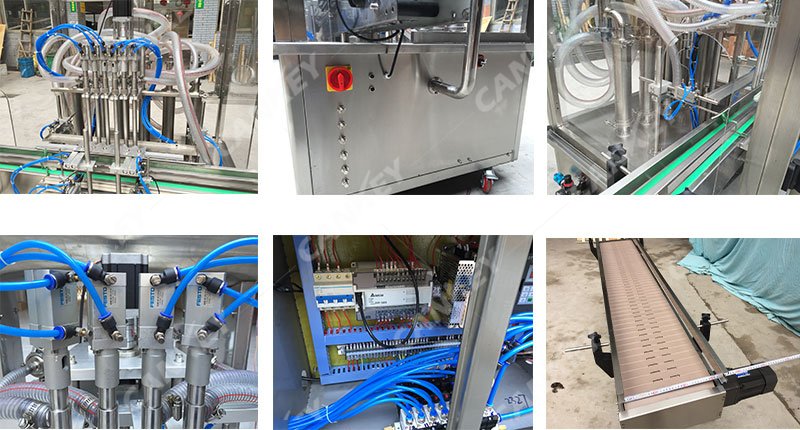

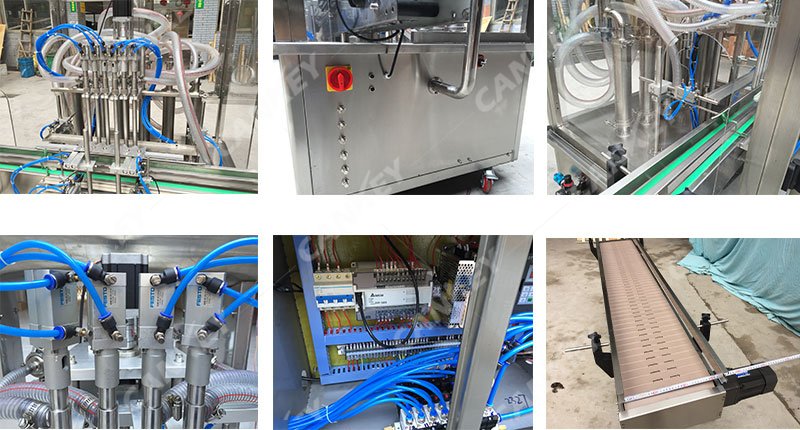

〇 Quick cleaning, easy adjustment, stepless speed regulation of volume cylinder action, the filling machine is suitable for different specifications and different materials.

〇 The filling amount is adjusted once, each volume cylinder can be adjusted slightly, and the filling accuracy is high, the consistency is good.

〇 The material in contact with the mango pulp is 316 stainless steel, silicone rubber, in line with QS specifications.

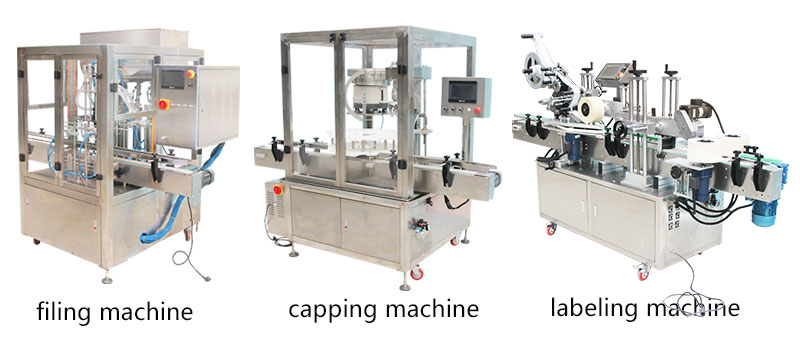

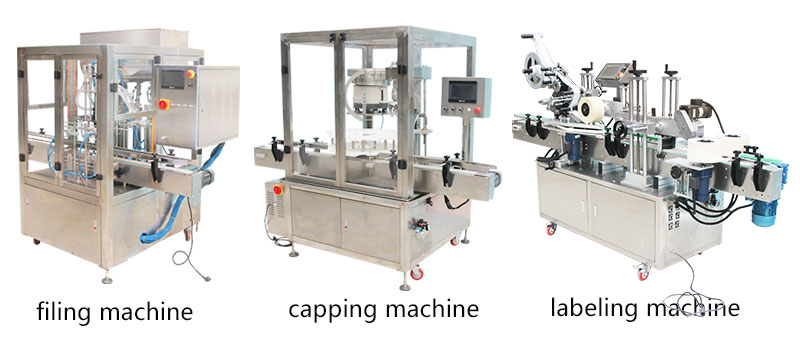

〇 the fruit pulp filling machine can equip with labeling machine, capping machine. And each machine can complete its work independently, with independent operating system, and electronic components such as numerical control display to control and adjust various parameters and display settings.

〇 Each machine is linked and separated quickly, and the adjustment is fast and simple, so that each process of production ensures coordination.

〇 The automatic jam filling machine with man-machine interface communicates, and the debugging equipment or replacement jam types only needs to be set on the screen.

Fruit Pulp Filling Machine Working Flow:

a. The bottles from the outlet of the unscrambler are automatically aligned to the same level, and then the bottle enters the aseptic filling machine.

b. There is a bottle quantity detection system on the automatic jam filling machine. When the number of bottles on the bottle feeding track reaches the preset position, the filling machine automatically starts running and completes the filling.

c. The bottle that has been filled will enter the capping machine through the conveyor track to complete the sealing process.

Automatic Jam Filling Machine Features:

〇 Quick cleaning, easy adjustment, stepless speed regulation of volume cylinder action, the filling machine is suitable for different specifications and different materials.

〇 The filling amount is adjusted once, each volume cylinder can be adjusted slightly, and the filling accuracy is high, the consistency is good.

〇 The material in contact with the mango pulp is 316 stainless steel, silicone rubber, in line with QS specifications.

〇 the fruit pulp filling machine can equip with labeling machine, capping machine. And each machine can complete its work independently, with independent operating system, and electronic components such as numerical control display to control and adjust various parameters and display settings.

〇 Each machine is linked and separated quickly, and the adjustment is fast and simple, so that each process of production ensures coordination.

〇 The automatic jam filling machine with man-machine interface communicates, and the debugging equipment or replacement jam types only needs to be set on the screen.

Technical Data

| Model | CK-GT4T-4G |

| Voltage | 220V 50/60Hz |

| Air Pressure | 0.5-0.7Mpa |

| SS Material | SUS304 |

| Pistion Material | PTFE |

| Main Cylinder | SMC(Japan) |

| PLC&Screen | Delta |

| Filling Volume Range | 100-1000ml |

| Filling Heads | 4 |

| Filling Speed | 16-20 Bottles/Min |

| Machine Size (L*W* H) | 2000*1050*1900 mm |

| Weight | 350Kg |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price