Automatic Sugar Sachet Packing Machine Manufacturers

Features

The use of sugar packing machine is mainly for:

✓ Increase productivity levels

✓ Simplified packaging process

✓ Fast ROI

According to the packaging requirements of each customer, different packaging equipment is required to meet. There are three commonly used types:

1. Small vertical. Small output, small footprint.

2. Multi-head scale. Suitable for large packaging. For example 1-5kg.

Use of Sugar Sachet Packing Machine for Sale:

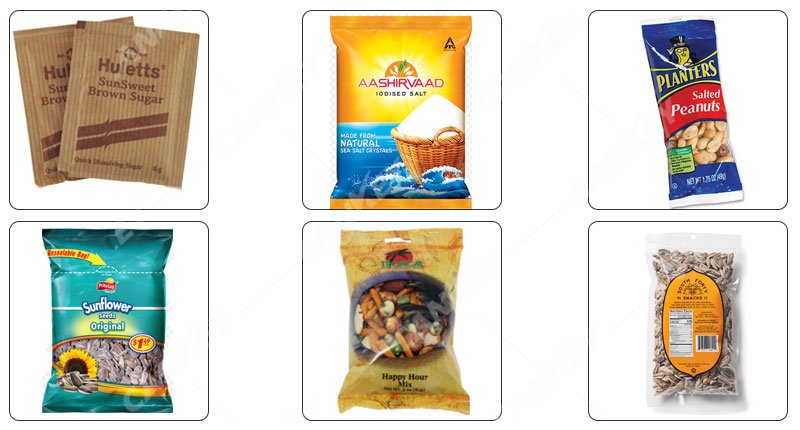

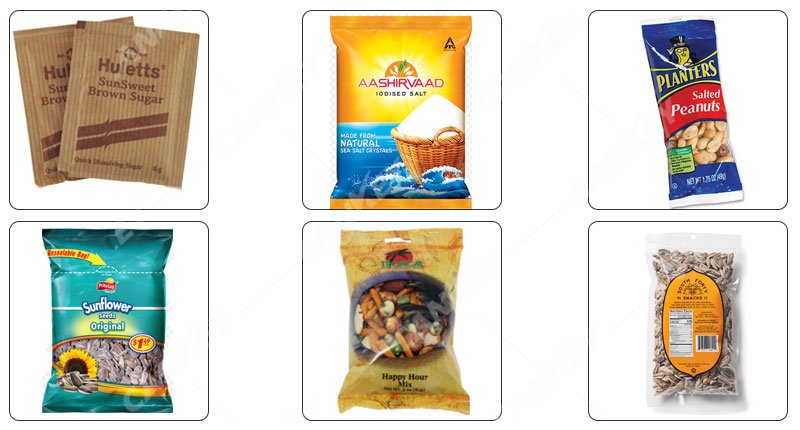

The packing materials include sugar, peanuts, melon seeds, vegetable seeds, popcorn, sweetener, cinnamon, salt, pepper and other particle products.

Automatic Sugar Packing Machine Features:

〇 Adopts PLC servo system and touch screen system. These two systems constitute the driving control center, which makes the whole machine and the intelligence degree reach the maximum.

〇 The error indication system of the machine is very sensitive and helpful for finding fault in time.

〇 The sugar sachet packing machine adopts the independent temperature control system, which makes the temperature of the machine more accurate in the packaging process and ensures the neat sealing effect.

〇 The machine has a safety protection system to ensure the safe operation of the machine.

Packing Range and Size of the Sugar Packing Machine:

This sugar packing machine can pack 10-100g of sugar (adjustable weight system), with high weighing accuracy and convenient and quick adjustment. (We will show customers the specific adjustment method)

Sugar Packing Machine Working Flow:

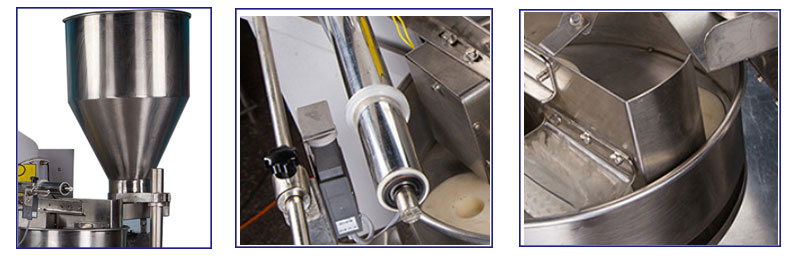

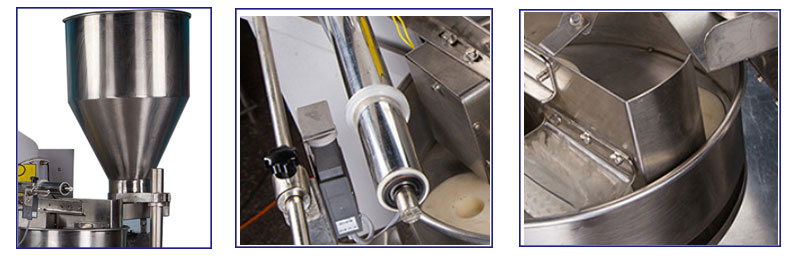

The packing film is loosened up from the film roll situated at the back part of the machine. Next, the packing film is sustained through an arrangement of nip rollers. From the nip rollers, the packing film goes into the cutting area. Amid this progression simultaneously, the film form into bag. Then sugar is put into the bag, and finally sealed and cut off. Packing is finished.

The machine uses a multi-head scale for weighing. The sugar falls into the cross-cut hopper of the combination scale through the elevator, and is vibrated by the vibrating machine, so that the sugar is evenly distributed on the conical funnel into the linear feeder pan. When there is no sugar or insufficient sugar in the cross-cutting hopper, it will be detected by the horizontal photoelectric detector, and a signal will be sent to the main board, and then a feeding signal will be sent to the conveyor through the main board for feeding. The sugar is vibrated through a linear feeder, and the product is sent to each buffer hopper by amplitude and vibration time. Then the driving equipment, that is, the stepping motor, works, and the buffer hopper is opened to send the sugar into the weighing hopper.

In the weighing hopper, the sugar generates the weight signal through the sensor, and then transmits it to the main board of the control device through the lead wire. The CPU on the main board reads and records the weight of each weighing bucket, and then selects the combined weighing bucket close to the target weight through calculation, analysis and combination. When the CPU receives the allowable discharge signal from the packaging machine, it sends a command to start the drive to open the collecting hopper to discharge the sugar to the packaging machine, and send a packaging signal to the sugar packaging machine.

✓ Increase productivity levels

✓ Simplified packaging process

✓ Fast ROI

According to the packaging requirements of each customer, different packaging equipment is required to meet. There are three commonly used types:

1. Small vertical. Small output, small footprint.

2. Multi-head scale. Suitable for large packaging. For example 1-5kg.

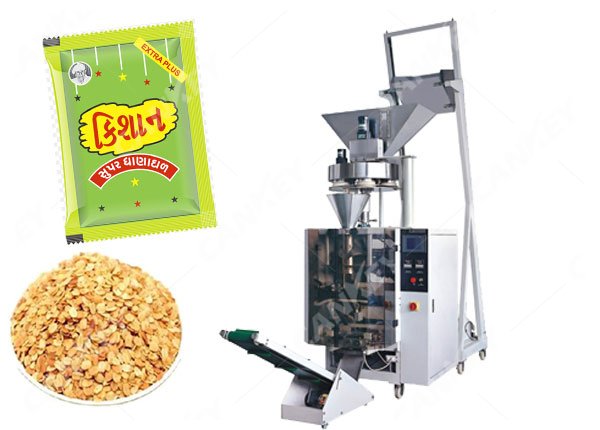

1. Small Sugar Sachet Packing Machine

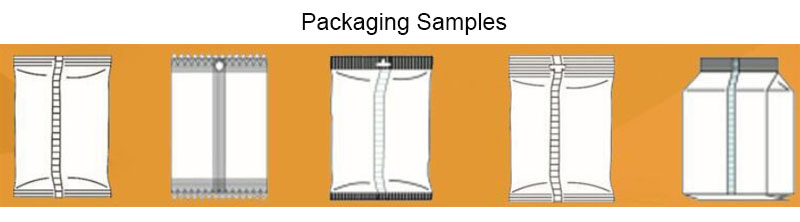

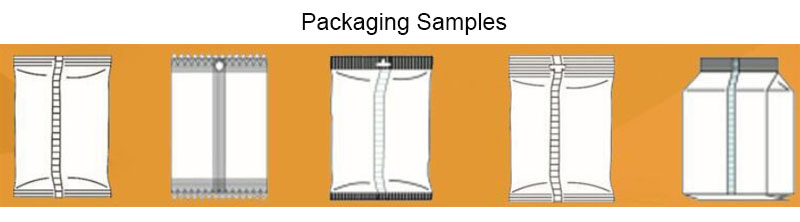

This sugar packing machine is an kind of particle packaging machines, which can realize different shapes of bag packing, such as back seal, three sides seal, four sides seal, etc.

Use of Sugar Sachet Packing Machine for Sale:

The packing materials include sugar, peanuts, melon seeds, vegetable seeds, popcorn, sweetener, cinnamon, salt, pepper and other particle products.

Automatic Sugar Packing Machine Features:

〇 Adopts PLC servo system and touch screen system. These two systems constitute the driving control center, which makes the whole machine and the intelligence degree reach the maximum.

〇 The error indication system of the machine is very sensitive and helpful for finding fault in time.

〇 The sugar sachet packing machine adopts the independent temperature control system, which makes the temperature of the machine more accurate in the packaging process and ensures the neat sealing effect.

〇 The machine has a safety protection system to ensure the safe operation of the machine.

Packing Range and Size of the Sugar Packing Machine:

This sugar packing machine can pack 10-100g of sugar (adjustable weight system), with high weighing accuracy and convenient and quick adjustment. (We will show customers the specific adjustment method)

Sugar Packing Machine Working Flow:

The packing film is loosened up from the film roll situated at the back part of the machine. Next, the packing film is sustained through an arrangement of nip rollers. From the nip rollers, the packing film goes into the cutting area. Amid this progression simultaneously, the film form into bag. Then sugar is put into the bag, and finally sealed and cut off. Packing is finished.

2. 1-5kg sugar packing machine

The machine uses a multi-head scale for weighing. The sugar falls into the cross-cut hopper of the combination scale through the elevator, and is vibrated by the vibrating machine, so that the sugar is evenly distributed on the conical funnel into the linear feeder pan. When there is no sugar or insufficient sugar in the cross-cutting hopper, it will be detected by the horizontal photoelectric detector, and a signal will be sent to the main board, and then a feeding signal will be sent to the conveyor through the main board for feeding. The sugar is vibrated through a linear feeder, and the product is sent to each buffer hopper by amplitude and vibration time. Then the driving equipment, that is, the stepping motor, works, and the buffer hopper is opened to send the sugar into the weighing hopper.In the weighing hopper, the sugar generates the weight signal through the sensor, and then transmits it to the main board of the control device through the lead wire. The CPU on the main board reads and records the weight of each weighing bucket, and then selects the combined weighing bucket close to the target weight through calculation, analysis and combination. When the CPU receives the allowable discharge signal from the packaging machine, it sends a command to start the drive to open the collecting hopper to discharge the sugar to the packaging machine, and send a packaging signal to the sugar packaging machine.

Technical Data

| Model | CK-LK320 |

| Power | 220V/1.8kw |

| Packaging Range | 10-100ml |

| Film Width | 80-280mm |

| Bag Size | L:30-180mm W:30-130mm |

| Machine Size | 820*980*1680mm |

| Machine Weight | 320kg |

| Film Thickness | 0.03mm-0.07mm |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price