Auger Spice Powder Filling Machine Equipment

Features

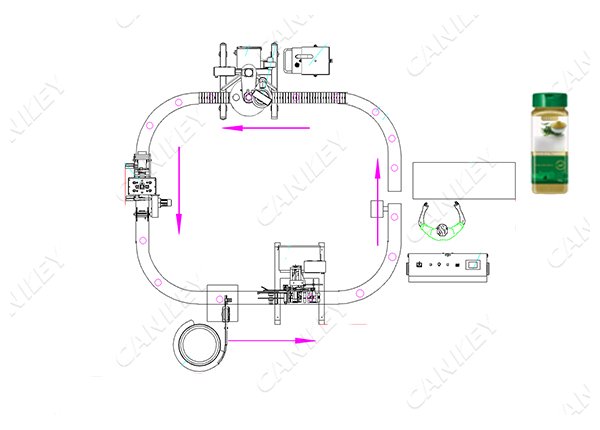

The spice powder filling machine is an economical and practical powder filling equipment, which can realize the positioning, metering and filling of packaging containers. The automatic powder filling equipment is generally composed of a feeding conveyor, a screw metering machine, a chain conveyor and a pneumatic positioning device. It can be combined with bottle unscrambler, capping machine, labeling machine, etc. to form a complete filling line.

It is suitable for automatic quantitative filling of bottled and canned powder products. Such as soda powder, nut powder, medicinal powder, pepper powder, spice powder, protein powder, talcum powder, milk powder, etc. quantitative filling of powder or small particles. Filling range of 5 grams to 5000 grams of any powder.

☺ The core devices of the machine are screw feeder, screw metering filling machine and chain plate conveying line with positioning device. This part is the main component of the powder filling machine, and together with the bottle unscrambler, sealing machine, capping machine, labeling machine and coding machine, it forms a complete set of automatic powder filling line. Semi-automatic filling can also be achieved if it is limited by factors such as site and capital.

☺ The spice powder filling machine integrates machine, electricity, light and instrument to realize automatic bottle unscrambling, conveying, feeding, metering, positioning, filling, sealing, capping, labeling, coding and other functions.

☺ The filling and metering device adopts screw quantitative, accurate metering, fast filling speed and high efficiency, and can be replaced with different specifications of the metering screw according to the filling amount.

☺ The control mode is displayed by PLC and English LCD touch screen. The adjustment parameter settings of a variety of products of different specifications can be stored, and the program can be switched according to the needs later, and the performance of the whole machine is more excellent.

☺ According to the characteristics of spices, a dust removal device can be installed, and the specially designed anti-leakage device ensures a cleaner and hygienic environment.

Spice Powder Filling Process:

Spices are usually a mixture of one or several materials, the filling process generally includes sorting, batching, mixing, filling, nitrogen filling, sealing, quality inspection, etc. Functional devices can be added according to actual packaging requirements.

Powder Filling Equipment Application:

It is suitable for automatic quantitative filling of bottled and canned powder products. Such as soda powder, nut powder, medicinal powder, pepper powder, spice powder, protein powder, talcum powder, milk powder, etc. quantitative filling of powder or small particles. Filling range of 5 grams to 5000 grams of any powder.

Spice Powder Filling Machine Features:

☺ The core devices of the machine are screw feeder, screw metering filling machine and chain plate conveying line with positioning device. This part is the main component of the powder filling machine, and together with the bottle unscrambler, sealing machine, capping machine, labeling machine and coding machine, it forms a complete set of automatic powder filling line. Semi-automatic filling can also be achieved if it is limited by factors such as site and capital.☺ The spice powder filling machine integrates machine, electricity, light and instrument to realize automatic bottle unscrambling, conveying, feeding, metering, positioning, filling, sealing, capping, labeling, coding and other functions.

☺ The filling and metering device adopts screw quantitative, accurate metering, fast filling speed and high efficiency, and can be replaced with different specifications of the metering screw according to the filling amount.

☺ The control mode is displayed by PLC and English LCD touch screen. The adjustment parameter settings of a variety of products of different specifications can be stored, and the program can be switched according to the needs later, and the performance of the whole machine is more excellent.

☺ According to the characteristics of spices, a dust removal device can be installed, and the specially designed anti-leakage device ensures a cleaner and hygienic environment.

Technical Data

| Model | CK-1 |

| Packing weight | 5-5000g (the screw attachment needs to be replaced) |

| packing accuracy | <±1% |

| Packing speed | 20-35bags/min (Detailed packing speed depends on manual, packaging materials) |

| Voltage | 3P/380V 50-60Hz |

| Power | 1.2kw |

| Weight | 220kg |

| Size | 750×600×1850mm |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price