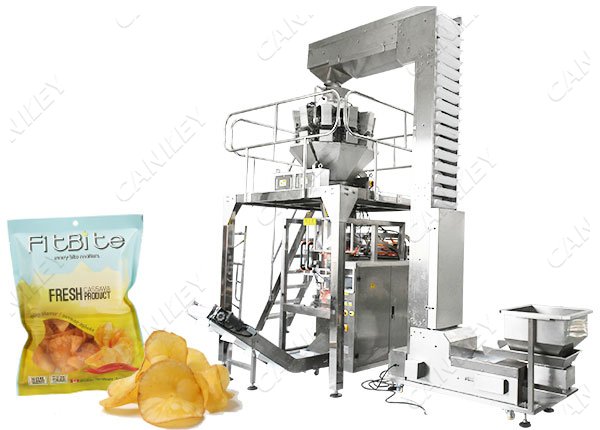

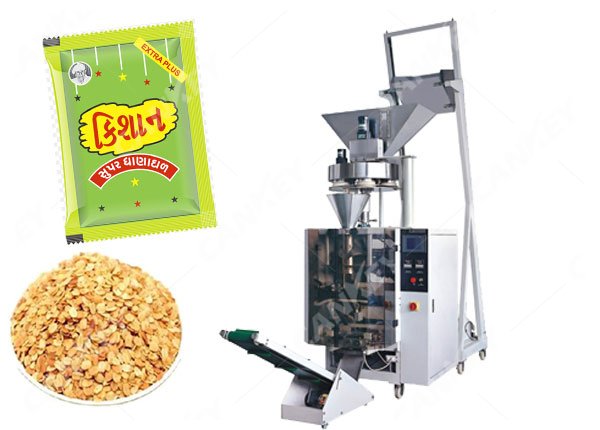

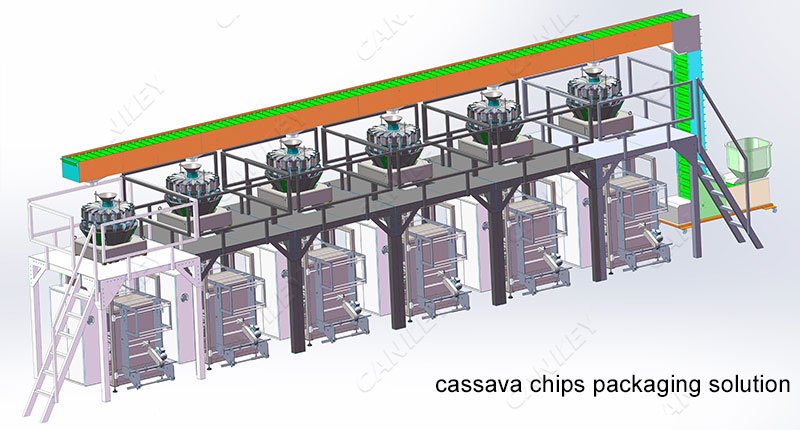

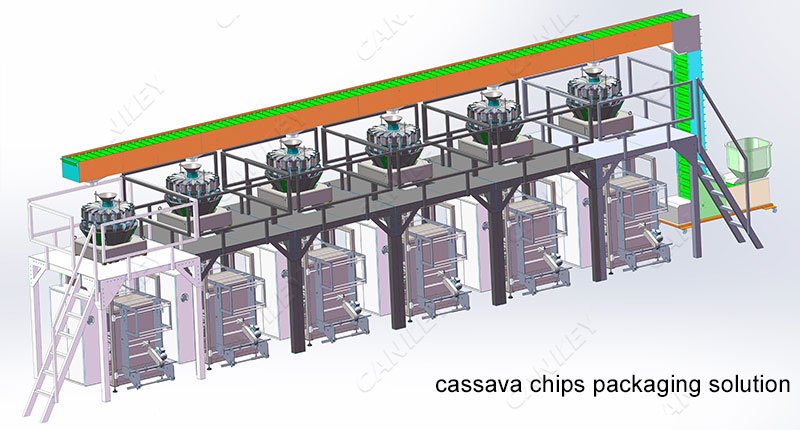

Tapioca Cassava Chips Packaging Machine/Durian Chips Packing Machine

Features

Cassava Chips Packaging Machine Working Principle:

The combination weigher tapioca chips packing machine is composed of multiple weighing units with independent feeding and discharging structure. The computer uses the principle of permutation and combination to automatically calculate the combination of the load amounts of each weighing unit to obtain the combination closest to the quantitative value for packaging.

For example, a 10 head weigher cassava chips packaging machine, during weighing, each weighing unit performs weighing and reads the weight data of each weighing hopper into the computer. The computer performs the optimal combination. According to the principle of mathematical combination, ten weighing units can realize a total of 1023 combinations. From these 1023 combinations, the computer selects a combination that is close to the target weight value.

Application of Tapioca Chips Packing Machine:

1. Fragile materials: potato chips, shrimp chips, french fries.

2. Bulk materials that are not easy to measure automatically: candy, jelly, bean sprouts, tea.

3. Small bag into big bag: Several small packages of medicine, food, daily necessities, etc. are put into one large package.

Durian Chips Packing Machine Features:

〇 Digital processing is performed by a special computer chip, which ensures that the weight analog signal is converted into a digital signal after fast digital filtering, thereby ensuring the normal operation of the "secondary data sampling" function.

〇 Due to the controllability of the stepping motor, the opening and closing speed and opening width of the weighing hopper can be adjusted, and the opening and closing of the weighing hopper can be adjusted small to achieve high speed during weighing.

〇 The amplitude and vibration time of the vibrating slot of the durian chips packing machine can be adjusted to meet customer requirements for accuracy and speed.

〇 There are corresponding application technologies according to different materials, such as waterproof, fragile, sticky, mixed weighing, etc., which can meet the needs of different customers.

The combination weigher tapioca chips packing machine is composed of multiple weighing units with independent feeding and discharging structure. The computer uses the principle of permutation and combination to automatically calculate the combination of the load amounts of each weighing unit to obtain the combination closest to the quantitative value for packaging.

For example, a 10 head weigher cassava chips packaging machine, during weighing, each weighing unit performs weighing and reads the weight data of each weighing hopper into the computer. The computer performs the optimal combination. According to the principle of mathematical combination, ten weighing units can realize a total of 1023 combinations. From these 1023 combinations, the computer selects a combination that is close to the target weight value.

Application of Tapioca Chips Packing Machine:

1. Fragile materials: potato chips, shrimp chips, french fries.

2. Bulk materials that are not easy to measure automatically: candy, jelly, bean sprouts, tea.

3. Small bag into big bag: Several small packages of medicine, food, daily necessities, etc. are put into one large package.

Durian Chips Packing Machine Features:

〇 Digital processing is performed by a special computer chip, which ensures that the weight analog signal is converted into a digital signal after fast digital filtering, thereby ensuring the normal operation of the "secondary data sampling" function.

〇 Due to the controllability of the stepping motor, the opening and closing speed and opening width of the weighing hopper can be adjusted, and the opening and closing of the weighing hopper can be adjusted small to achieve high speed during weighing.

〇 The amplitude and vibration time of the vibrating slot of the durian chips packing machine can be adjusted to meet customer requirements for accuracy and speed.

〇 There are corresponding application technologies according to different materials, such as waterproof, fragile, sticky, mixed weighing, etc., which can meet the needs of different customers.

Technical Data

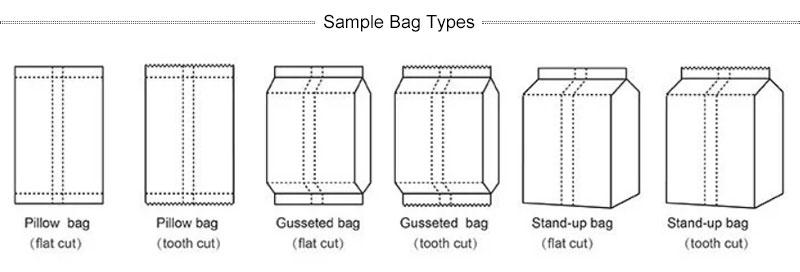

| Model | CK-LK720 |

| Film width | max 720mm |

| Bag width | 110-350mm |

| Bag length | 100-420mm |

| Packing speed | 10-50bags/min |

| Packing range | 150-4000ml |

| Film thickness | 0.04-0.10mm |

| Power | 4kw/220v 50-60Hz |

| Machine size | 1780*1350*2000mm |

| Machine weight | 800kg |

| Air consumption | 0.8m³/min 0.8mpa |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price