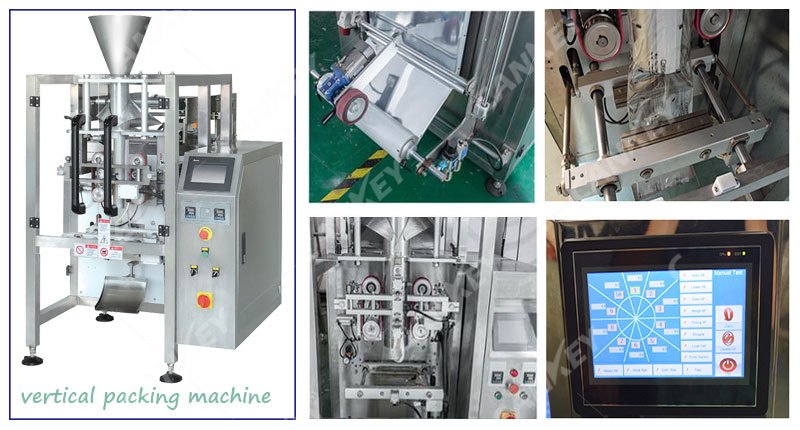

Automatic Chifles Chips Packaging Machine with Nitrogen

Features

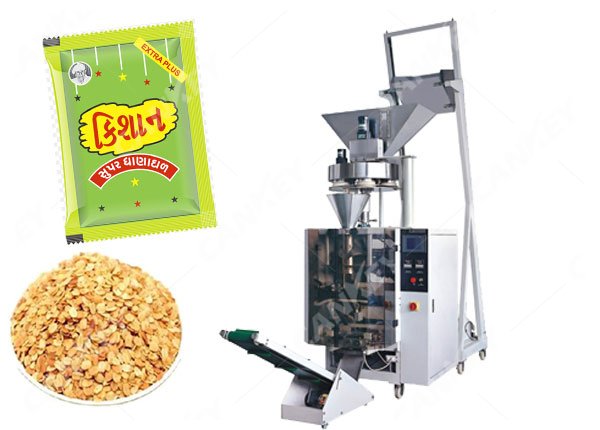

Chifles Packaging Machine Scope of Application:

This chips packing machine with nitrogen is suitable for bulk materials that require high precision and fragility, such as pistachio, melon seeds, potato chips, plantain chips, etc. Quantitative weighing packaging of various granules, flakes, strips, and other irregular shapes.

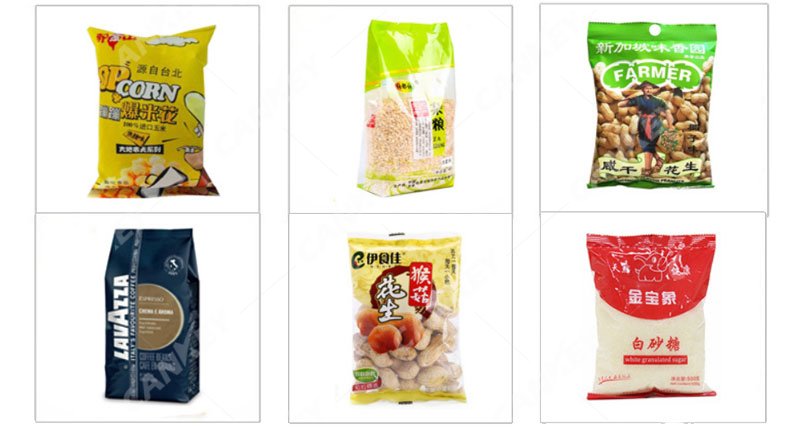

Bag Types of Chifles Packaging Machine:

Diversified products, back seals, gussets, four-sided seals, standing bags, punching, etc.

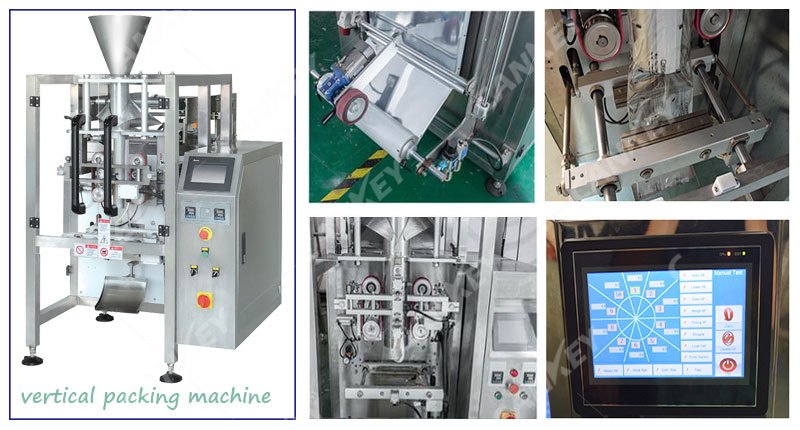

Chips Packing Machine with Nitrogen Working Principle:

Turn on the power and set the temperature to constant temperature→Setting parameters (bag size and package weight)→Manually feeding to the storage hopper, vibrating and feeding to the lifting conveyor→The material hoist starts to transport materials→Electronic combination scale measurement→Print production date→Bag making→Filling→Gas-filled→Sealing→Cutting→Finished product output

Chifles Packaging Machine Features:

〇 Independent temperature control system with an accuracy of ±1 °C.

〇 PLC computer control system, running more stable, can adjust any parameters without stopping.

〇 This chips packing machine with nitrogen can store ten sets of parameters and replace the materials more accurately.

O Automatic fault alarm display function, such as low temperature, no packaging film, no ribbon, no material, servo failure, no color label signal, automatic alarm or shutdown function when the glass protective door is opened.

Combination Scale Features:

◎ The perfect combination of high precision and high speed, through computer computing, choose the right combination from the rich weight combination.

◎ The high-precision digital weighing sensor enables the measurement to be realized instantaneously, and the Chinese/English and other languages of the LCD operating system.

◎ According to the characteristics of the object to be measured, the opening and closing speed of the hopper door can be finely adjusted to prevent breakage and jamming.

This chips packing machine with nitrogen is suitable for bulk materials that require high precision and fragility, such as pistachio, melon seeds, potato chips, plantain chips, etc. Quantitative weighing packaging of various granules, flakes, strips, and other irregular shapes.

Bag Types of Chifles Packaging Machine:

Diversified products, back seals, gussets, four-sided seals, standing bags, punching, etc.

Chips Packing Machine with Nitrogen Working Principle:

Turn on the power and set the temperature to constant temperature→Setting parameters (bag size and package weight)→Manually feeding to the storage hopper, vibrating and feeding to the lifting conveyor→The material hoist starts to transport materials→Electronic combination scale measurement→Print production date→Bag making→Filling→Gas-filled→Sealing→Cutting→Finished product output

Chifles Packaging Machine Features:

〇 Independent temperature control system with an accuracy of ±1 °C.

〇 PLC computer control system, running more stable, can adjust any parameters without stopping.

〇 This chips packing machine with nitrogen can store ten sets of parameters and replace the materials more accurately.

O Automatic fault alarm display function, such as low temperature, no packaging film, no ribbon, no material, servo failure, no color label signal, automatic alarm or shutdown function when the glass protective door is opened.

| Model | CK-LK1000 |

| Film width | max 1050mm |

| Bag width | 100-500mm |

| Bag length | 150-700mm |

| Packing speed | 5-25bags/min |

| Packing range | 300-5000ml |

| Film thickness | 0.04-0.10mm |

| Power | 4.2kw/220v 50-60Hz |

| Machine size | 2090*1870*2910mm |

| Machine weight | 1200kg |

| Air consumption | 1.5m³/min 0.8mpa |

Combination Scale Features:

◎ The perfect combination of high precision and high speed, through computer computing, choose the right combination from the rich weight combination.

◎ The high-precision digital weighing sensor enables the measurement to be realized instantaneously, and the Chinese/English and other languages of the LCD operating system.

◎ According to the characteristics of the object to be measured, the opening and closing speed of the hopper door can be finely adjusted to prevent breakage and jamming.

| Model | CK-A14-1.6 | CK-A10-1.6 |

| Voltage | AC110/220V | AC110/220V |

| Power frequency | 50/60HZ | 50/60HZ |

| Rated current | 10A | 8A |

| Power | 2.0KW | 1.5KW |

| Weighing heads | 14 | 10 |

| Weighing range | 3-6500g | 3-6500g |

| Single weighing range | 10-1200g | 10-1000g |

| Weighing volume | 1600ml | 1600ml |

| Max weighing speed | 130p/min | 70p/min |

| Preset number | 100 | 100 |

| Machine length | 1020mm | 1050mm |

| Machine width | 960mm | 900mm |

| Machine height | 1400mm | 1330mm |

| Machine weight | 420KG | 330KG |

| Monitor | 13.6inch | 9.2inch |

| Precision | ±0.3-3g | ±0.3-3g |

Technical Data

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price