New Version Digital Control Particle Filling Machine for Nuts

Features

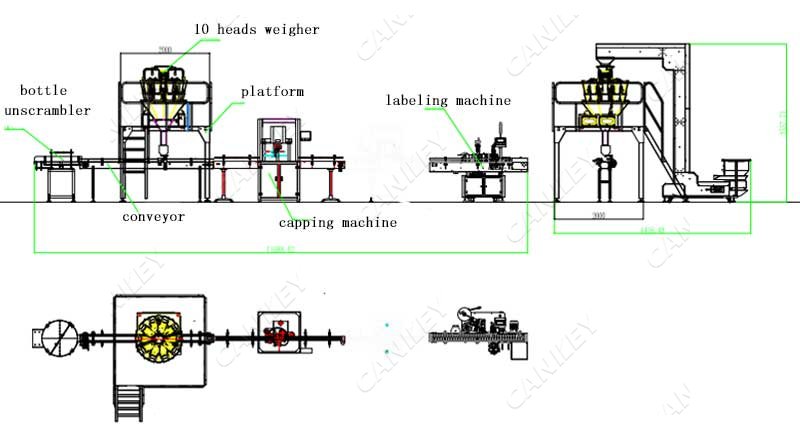

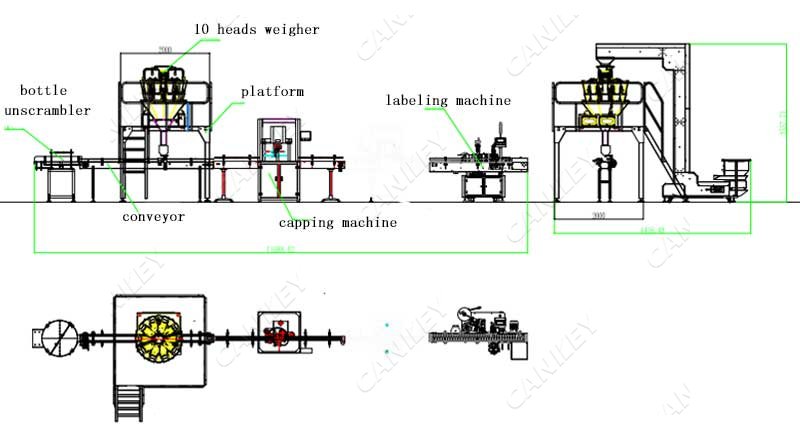

Bottled nuts filing line consists of Z-type elevator, new version digital control particle filling machine, capping machine, labeling machine. It can automatically complete the bottling process of granules such as nuts, candy, snack, etc., so as to complete the automated assembly line production.

Nuts Filling Machine Structural Features:

〇 The work operation is fully automated, and there is an automatic interlock protection device. The nuts filling machine is equipped with two operating modes, intermittent operation and continuous operation.

〇 Particle weighing and filling machine adopts advanced PLC + servo motor + touch screen advanced mode.

〇 The entire filling process uses an intelligent control system that can complete the automatic positioning, filling and metering of bottles.

〇 The digital control particle filling machine is equipped with a reasonable height adjustment hand wheel, which is convenient for adjusting the height of the machine head.

〇 The whole filling line has stable performance, reliable work, high efficiency, and low failure rate. It is the ideal choice to realize automated production.

Particle Weighing and Filling Machine Characteristic:

〇 New advanced modular control system.

〇 The automatic amplitude adjustment function makes the debugging more convenient.

〇 Can weigh a variety of different materials at the same time to achieve mixed material packaging.

〇 According to production conditions, parameters can be directly modified during operation, and the operation is simple.

〇 Stepless vibration machine feeding system is used to make the material more uniform and the weighing range is larger.

Supporting Devices of Digital Control Particle Filling Machine:

Pneumatic valve device, leak-proof centrifugal device, tank support device, dust removal device.

Related Products:

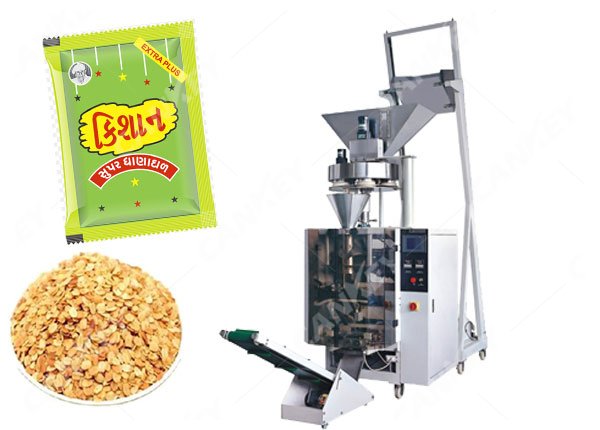

Nuts Pouch Packing Machine

Nuts Filling Machine Structural Features:

〇 The work operation is fully automated, and there is an automatic interlock protection device. The nuts filling machine is equipped with two operating modes, intermittent operation and continuous operation.

〇 Particle weighing and filling machine adopts advanced PLC + servo motor + touch screen advanced mode.

〇 The entire filling process uses an intelligent control system that can complete the automatic positioning, filling and metering of bottles.

〇 The digital control particle filling machine is equipped with a reasonable height adjustment hand wheel, which is convenient for adjusting the height of the machine head.

〇 The whole filling line has stable performance, reliable work, high efficiency, and low failure rate. It is the ideal choice to realize automated production.

Particle Weighing and Filling Machine Characteristic:

〇 New advanced modular control system.

〇 The automatic amplitude adjustment function makes the debugging more convenient.

〇 Can weigh a variety of different materials at the same time to achieve mixed material packaging.

〇 According to production conditions, parameters can be directly modified during operation, and the operation is simple.

〇 Stepless vibration machine feeding system is used to make the material more uniform and the weighing range is larger.

Supporting Devices of Digital Control Particle Filling Machine:

Pneumatic valve device, leak-proof centrifugal device, tank support device, dust removal device.

Related Products:

Nuts Pouch Packing Machine

Technical Data

| Item | Quantity | Main data |

| Z type hoist | 1 | 3.05M |

| Platform | 1 | / |

| Multihead weigher | 1 | / |

| Capping machine | 1 | 30-45bottles/min |

| Bottle sorting machine | 1 | 10-80 bottles/min |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price