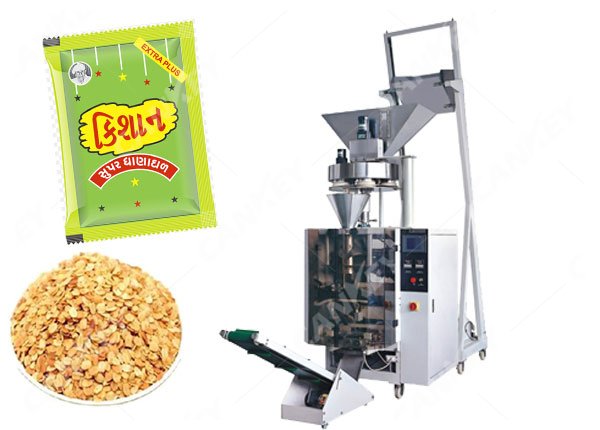

Fried Potato Chip Packaging Machine for Sale(Filling Nitrogen)

Features

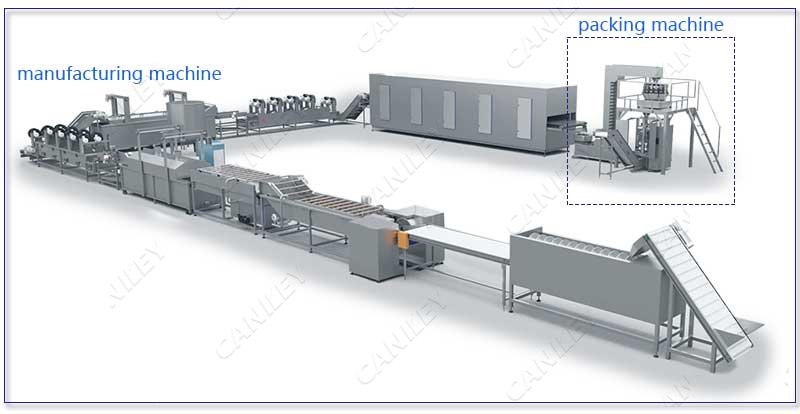

This fried chips packing machine is widely used in chips plant, can be used in conjunction with potato chip making machine to form an automated production line. The potato chip packaging machine for sale can also be used for packaging banana chips, plantain chips, and French fries. And in order to prevent fried chips from being damaged during transportation, nitrogen can be flushed into the chips packet.

Characteristics:

1. The fried chips packing machine weighs automatically, which is good for food safety.

2. Fast weighing speed

3. High dynamic weighing accuracy

4. High degree of automation

5. The hopper is made of patterned steel plate to prevent fried chips from sticking to the hopper wall.

The use of automatic fried chips packing machine can save raw materials, improve labor conditions, reduce labor intensity, reduce product costs, and protect the environment. Automatic packing greatly improves production efficiency and completes the specialization of packaging fried chips, which cannot be achieved by manual packaging. Automatic packaging saves capital investment and reduces the area of the packaging site. When manually packaging fried chips, due to the large number of workers, the inconsistent process, and the large footprint of the packaging work, it is the trend of chips manufacturing to use automatic packaging instead of manual packaging. It not only improves the quality of fried chips packaging, but also ensures the cleanness and safety of the fried chips, and enhances the competitiveness of market sales.

Profit Comparison:

Compared with the general electronic weigher, the 10-head combination weigher for quantitative weighing can complete the same work:

(1) Requires 1 set of 10-head combined weigher, 2 operators, speed 60 bags/min. Single bag error 0.3~0.5 grams, the total error per day is about 14 kg, and the total error per year is about 4 tons.

(2) Ordinary electronic weigher need 5 sets, 10 operators, 12 bags/min. The error of a single bag is 3 grams, the total error per day is 86 kg, and the total error per year is 26 tons.

Obviously, if the combined weigher is used, the manufacturer can save 8 manpower and 22 tons of raw materials every year.

Due to the fragility and light weight of chips, we recommend that you use a multi-head weigher to achieve precise packaging.

Characteristics:1. The fried chips packing machine weighs automatically, which is good for food safety.

2. Fast weighing speed

3. High dynamic weighing accuracy

4. High degree of automation

5. The hopper is made of patterned steel plate to prevent fried chips from sticking to the hopper wall.

Why Recommend the Automatic Fried Chips Packing Machine to You?

The use of automatic fried chips packing machine can save raw materials, improve labor conditions, reduce labor intensity, reduce product costs, and protect the environment. Automatic packing greatly improves production efficiency and completes the specialization of packaging fried chips, which cannot be achieved by manual packaging. Automatic packaging saves capital investment and reduces the area of the packaging site. When manually packaging fried chips, due to the large number of workers, the inconsistent process, and the large footprint of the packaging work, it is the trend of chips manufacturing to use automatic packaging instead of manual packaging. It not only improves the quality of fried chips packaging, but also ensures the cleanness and safety of the fried chips, and enhances the competitiveness of market sales.Profit Comparison:

Compared with the general electronic weigher, the 10-head combination weigher for quantitative weighing can complete the same work:

(1) Requires 1 set of 10-head combined weigher, 2 operators, speed 60 bags/min. Single bag error 0.3~0.5 grams, the total error per day is about 14 kg, and the total error per year is about 4 tons.

(2) Ordinary electronic weigher need 5 sets, 10 operators, 12 bags/min. The error of a single bag is 3 grams, the total error per day is 86 kg, and the total error per year is 26 tons.

Obviously, if the combined weigher is used, the manufacturer can save 8 manpower and 22 tons of raw materials every year.

Potato Chip Packaging Material:

The packaging materials can be heat-sealed packaging materials such as PE/polyethylene, PE/aluminized, pet/PE, pp, etc. Most of them are composite packaging films.

Technical Data

| Model | LK520 | LK420 |

| Film width | max 520mm | max 420mm |

| Bag width | 90-250mm | 80-200mm |

| Bag length | 80-350mm | 50-300mm |

| Packing speed | 10-70bags/min | 15-80bags/min |

| Packing range | 150-2000ml | 150-1500ml |

| Film thickness | 0.04-0.10mm | 0.04-0.10mm |

| Power | 3kw/220v 50-60Hz | 2.5kw/220v 50-60Hz |

| Machine size | 1430*1200*1700mm | 1400*970*1700mm |

| Machine weight | 650kg | 450kg |

| Air consumption | 0.4m³/min 0.6mpa | 0.4m³/min 0.6mpa |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price