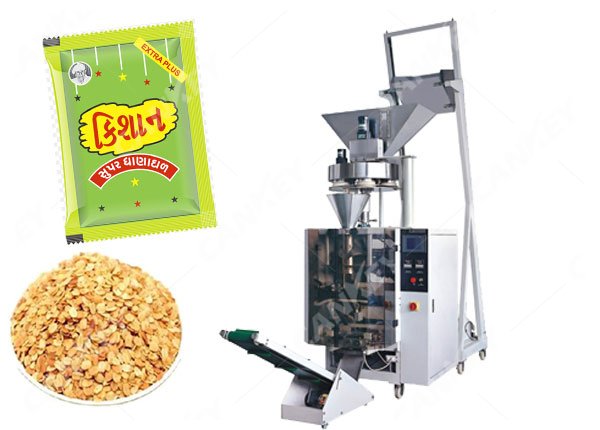

Industrial Frozen Dumpling Food Packaging Machine

Features

The frozen food packaging machine is mainly composed of a combination weigher, a vertical packaging machine, a vibrating feeder, a Z-type conveyor, a support platform. The weighing speed and accuracy mainly depend on the number of participating weighing hopper. The more weighing hopper, the faster the weighing speed, and the more accurate the weighing accuracy.

Frozen Dumpling Packing Machine Features:

O Concave-convex scale bucket is used to prevent materials from sticking to the weighing bucket.

O The frozen food packaging machine uses a servo motor to pull the film for more accurate positioning.

O The machine uses an independent temperature control system with an accuracy of ± 1℃.

O The frozen dumpling packing machine adopts a PLC computer control system for more stable operation and can adjust parameters without stopping.

O The horizontal and vertical sealing temperatures are independently controlled, which can better apply to various composite films, PE films and other packaging materials.

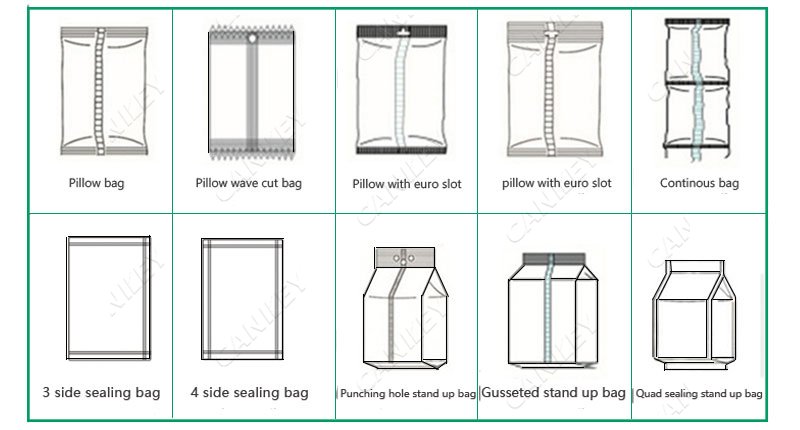

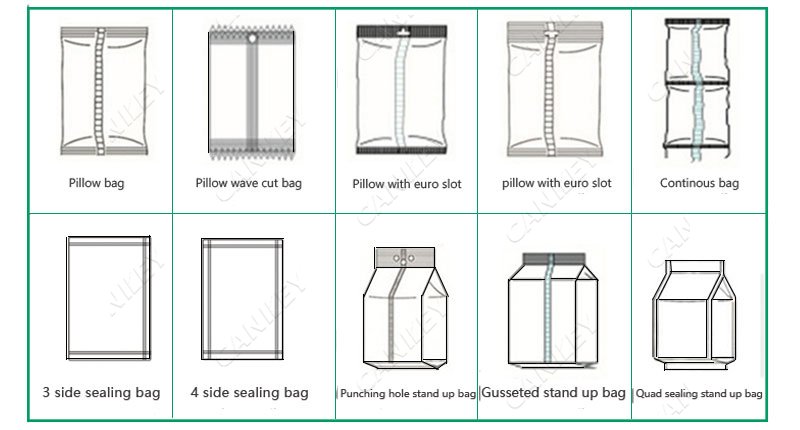

O Variety of finished products, such as back seals, gussets, four-side ironing, four-side seals, standing bags, punching, etc.

Note:

When choosing a frozen food packaging machine, you should consider the characteristics of the product's weighing range, material size, shape, and viscosity. If the weighing range and material are large, you should consider using a combination scale with 14 heads and more.

If the material is sticky, the feeding hopper and weighing hopper in contact with the material should be anti-sticky. Generally, a concave-convex scale hopper is selected, otherwise the speed and accuracy of the frozen dumpling packing machine will be affected.

Frozen Dumpling Packing Machine Features:

O Concave-convex scale bucket is used to prevent materials from sticking to the weighing bucket.

O The frozen food packaging machine uses a servo motor to pull the film for more accurate positioning.

O The machine uses an independent temperature control system with an accuracy of ± 1℃.

O The frozen dumpling packing machine adopts a PLC computer control system for more stable operation and can adjust parameters without stopping.

O The horizontal and vertical sealing temperatures are independently controlled, which can better apply to various composite films, PE films and other packaging materials.

O Variety of finished products, such as back seals, gussets, four-side ironing, four-side seals, standing bags, punching, etc.

Note:

When choosing a frozen food packaging machine, you should consider the characteristics of the product's weighing range, material size, shape, and viscosity. If the weighing range and material are large, you should consider using a combination scale with 14 heads and more.

If the material is sticky, the feeding hopper and weighing hopper in contact with the material should be anti-sticky. Generally, a concave-convex scale hopper is selected, otherwise the speed and accuracy of the frozen dumpling packing machine will be affected.

Technical Data

| Model | CK-LK720 |

| Film width | max 720mm |

| Bag width | 110-350mm |

| Bag length | 100-420mm |

| Packing speed | 10-50bags/min |

| Packing range | 150-4000ml |

| Film thickness | 0.04-0.10mm |

| Power | 4kw/220v 50-60Hz |

| Machine size | 1780*1350*2000mm |

| Machine weight | 800kg |

| Air consumption | 0.8m³/min 0.8mpa |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price