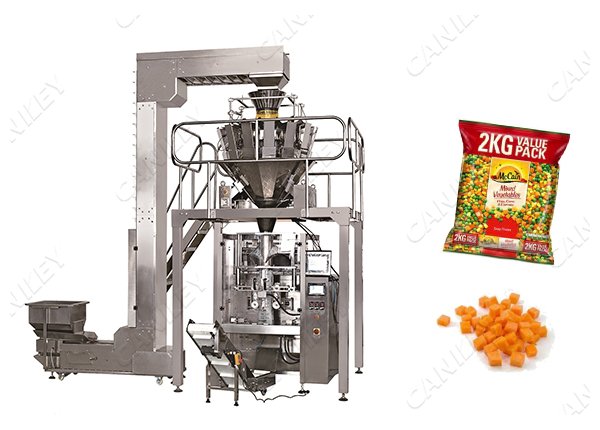

Frozen Vegetable Green Peas Packaging Machine Plant

Features

This frozen vegetable packaging machine is designed and engineered for applications with tight accuracy and high speed production requirements. This versatile packaging machine is perfect for dispensing a wide range of frozen vegetable including green peas, corn, carrot, broccoli, cauliflower, etc.

Frozen Vegetable Packaging Machine Working Principle:

our company offer in 10, 14, 16 and 24 heads configuration, each head (or lane) includes a dedicated load cell. The process starts by filling the center of the scale with bulk vegetables; vegetable will then vibrate from the center cone to the individual vibratory feeder pans. These feeder pans will transport vegetable to the weigh bucket where it will be weighed and measured. Once weighed, the PC will determine which buckets equal a near perfect match, once that match is chosen it is then locked and the buckets will dispense at the same time to the automatic packaging machine.

Frozen Green Peas Packaging Machine Features:

☆High precision, small target weighing, combination of high precision and high speed.

☆Simple high-speed operation, microcomputer control, touch screen display, easy operation and maintenance.

☆Precise positioning, servo-controlled pulling film, accurate positioning of the pulling film, automatic tracking by the electric eye, accurate positioning of the trademark.

☆Quick return on investment: Save raw materials and labor to a large extent.

☆When the door is opened under any circumstances, the bucket will automatically stop the operation of the machine and give an alarm, which meets the safety requirements.

Frozen Green Peas Packaging Machine Common Collocations:

Manual splicing system: It is mainly used for manual bag filling and packaging, which occupies small space and low cost. The system mainly consists of a multi-head weigher, a platform, a collection hopper, a set of material distribution mechanism.

Vertical packing system: The system realizes fully automatic filling and packaging, and has the advantages of fast packaging speed and labor saving. The system is mainly composed of a hoist, a multi-head weigher, a platform, and a vertical packaging machine.

Multihead weigher with one for two system: This system mainly makes full use of the high speed and stability of the combination weigher. It fully embodies the packaging, which has the advantages of fast speed, resource saving, and high space utilization. The system is mainly composed of one elevator, one high-speed multi-head weigher, one platform, one collecting hopper, one set of distribution mechanism, and two vertical packaging machines.

Canning system: This system realizes the full-automatic weighing, filling and packaging of can-shaped series. It has the advantages of fast speed, high precision, stability, and high degree of automation. The system is mainly composed of a large inclination hoist, a multi-head weigher, a platform, a collecting hopper, and a canning conveyor.

Frozen Vegetable Packaging Machine Working Principle:

our company offer in 10, 14, 16 and 24 heads configuration, each head (or lane) includes a dedicated load cell. The process starts by filling the center of the scale with bulk vegetables; vegetable will then vibrate from the center cone to the individual vibratory feeder pans. These feeder pans will transport vegetable to the weigh bucket where it will be weighed and measured. Once weighed, the PC will determine which buckets equal a near perfect match, once that match is chosen it is then locked and the buckets will dispense at the same time to the automatic packaging machine.

Frozen Green Peas Packaging Machine Features:

☆High precision, small target weighing, combination of high precision and high speed.

☆Simple high-speed operation, microcomputer control, touch screen display, easy operation and maintenance.

☆Precise positioning, servo-controlled pulling film, accurate positioning of the pulling film, automatic tracking by the electric eye, accurate positioning of the trademark.

☆Quick return on investment: Save raw materials and labor to a large extent.

☆When the door is opened under any circumstances, the bucket will automatically stop the operation of the machine and give an alarm, which meets the safety requirements.

Frozen Green Peas Packaging Machine Common Collocations:

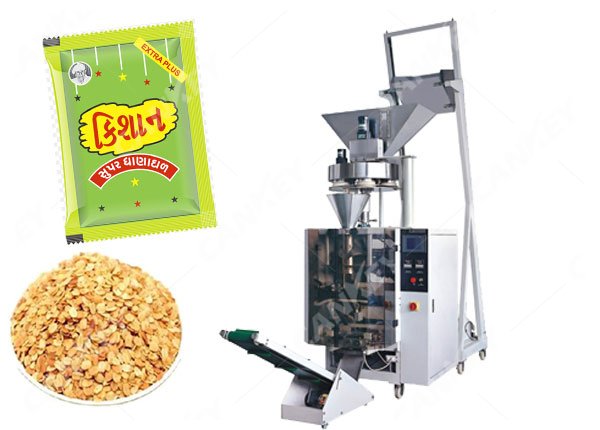

Manual splicing system: It is mainly used for manual bag filling and packaging, which occupies small space and low cost. The system mainly consists of a multi-head weigher, a platform, a collection hopper, a set of material distribution mechanism.

Vertical packing system: The system realizes fully automatic filling and packaging, and has the advantages of fast packaging speed and labor saving. The system is mainly composed of a hoist, a multi-head weigher, a platform, and a vertical packaging machine.

Multihead weigher with one for two system: This system mainly makes full use of the high speed and stability of the combination weigher. It fully embodies the packaging, which has the advantages of fast speed, resource saving, and high space utilization. The system is mainly composed of one elevator, one high-speed multi-head weigher, one platform, one collecting hopper, one set of distribution mechanism, and two vertical packaging machines.

Canning system: This system realizes the full-automatic weighing, filling and packaging of can-shaped series. It has the advantages of fast speed, high precision, stability, and high degree of automation. The system is mainly composed of a large inclination hoist, a multi-head weigher, a platform, a collecting hopper, and a canning conveyor.

Technical Data

| Model | CK-LK720 |

| Film width | max 720mm |

| Bag width | 110-350mm |

| Bag length | 100-420mm |

| Packing speed | 10-50bags/min |

| Packing range | 150-4000ml |

| Film thickness | 0.04-0.10mm |

| Power | 4kw/220v 50-60Hz |

| Machine size | 1780*1350*2000mm |

| Machine weight | 800kg |

| Air consumption | 0.8m³/min 0.8mpa |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price