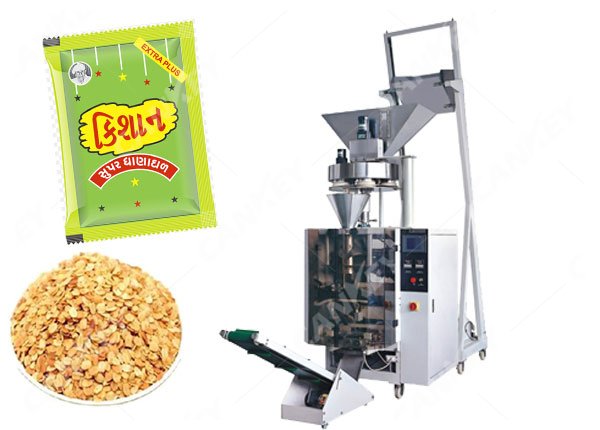

Multifunctional Quantitative Grain Filling Machine New Version

Features

This grain filling machine is an intelligent weighing type multifunctional quantitative filling machine. There are a variety of models such as single scale, double scale, four scale, etc. Microcomputer control, suitable for quantitative packaging of granular materials such as pesticides, fertilizers, veterinary drugs, additives, grains, seeds, nuts, rice, snack foods, etc.

○ Automatic feeding, automatic stop.

○ The four scales work alternately, make the packaging speed faster.

○ Program modular design, PLC control system, man-machine interface operation.

○ Three-level vibration feeding realizes high-precision packaging.

○ The part in contact with the grain is made of high-quality stainless steel, which is anti-corrosion, dust-proof and easy to clean.

○ Using cans or bottle-shaped containers, equipped with automatic feeding system, can realize no bottle no filling.

○ The automatic multifunctional quantitative filling machine has the function of weight over-tolerance alarm and fault alarm prompting, not to let each bottle of unqualified product be missed, and to ensure the product qualification rate.

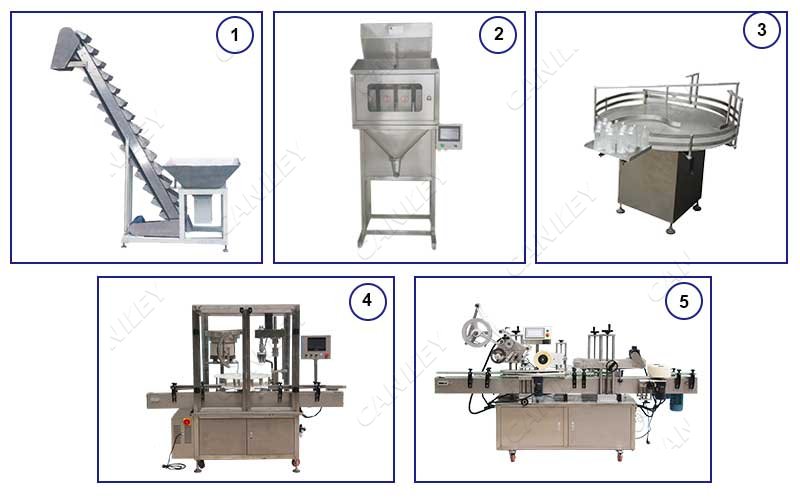

Capping machine:

It is a kind of sealing machine, which is widely used for sealing glass bottles or PET bottles.

1. It is suitable for screw capping of duckbill caps, screw caps, anti-theft ring caps, etc.

2. Electric control movement, rotating speed of capping can be adjusted freely.

3. Positioning device, easy to operate, high production efficiency, stable performance.

4. A wide range of screw caps can be used for bottle caps of different diameters.

5. The capping speed is adjustable, and the tightness can be adjusted according to different caps.

Labeling machine:

Used for automatic labeling of containers in the pharmaceutical, daily chemical, food and other industries.

1. Intelligent control: With automatic detection of label length and remaining label alarm function.

2. Labeling parameter storage: Preset 50 sets of labeling parameters (including bottle diameter and label length), no need to reset when changing the bottle.

Grain Filling Machine Working Principle:

Adopting direct current and vibrating feed, the grain enters the buffer silo through the vibrator. The grain is sent to the bottle through the feeding vibration controlled by the frequency conversion.

Multifunctional Grain Filling Machine Features:

○ Automatic feeding, automatic stop.○ The four scales work alternately, make the packaging speed faster.

○ Program modular design, PLC control system, man-machine interface operation.

○ Three-level vibration feeding realizes high-precision packaging.

○ The part in contact with the grain is made of high-quality stainless steel, which is anti-corrosion, dust-proof and easy to clean.

○ Using cans or bottle-shaped containers, equipped with automatic feeding system, can realize no bottle no filling.

○ The automatic multifunctional quantitative filling machine has the function of weight over-tolerance alarm and fault alarm prompting, not to let each bottle of unqualified product be missed, and to ensure the product qualification rate.

Used in conjunction with capping machine and labeling machine to form an automatic grain filling line with faster packaging speed.

Capping machine:It is a kind of sealing machine, which is widely used for sealing glass bottles or PET bottles.

1. It is suitable for screw capping of duckbill caps, screw caps, anti-theft ring caps, etc.

2. Electric control movement, rotating speed of capping can be adjusted freely.

3. Positioning device, easy to operate, high production efficiency, stable performance.

4. A wide range of screw caps can be used for bottle caps of different diameters.

5. The capping speed is adjustable, and the tightness can be adjusted according to different caps.

Labeling machine:

Used for automatic labeling of containers in the pharmaceutical, daily chemical, food and other industries.

1. Intelligent control: With automatic detection of label length and remaining label alarm function.

2. Labeling parameter storage: Preset 50 sets of labeling parameters (including bottle diameter and label length), no need to reset when changing the bottle.

Technical Data

| Model | multifunctional quantitative filling machine |

| Power | 4000W |

| Machine weighet | 180kg |

| Packing speed | 10-20/min |

| Packaging accuracy | ±2g |

| Packing specification | 100-1000g |

| Machine size | 1250*1000*2100mm |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price