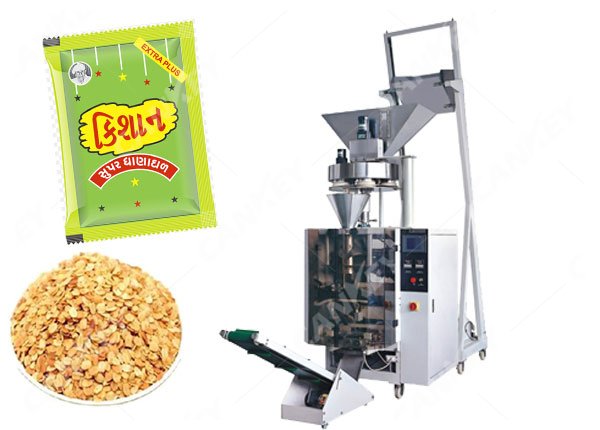

Fried Onion Rings/ Pork Rinds Packaging Machine

Features

Packaging is very important and necessary for fried food. Why? Plastic film helps to control the oxidation of the product and the loss or increase of moisture, aroma and grease, thereby improving the quality of the product and extending the shelf life.

Which Packaging Machine Is Better for Packaging Fried Pork Rinds/Onion Rings?

Generally, we will provide customers with different types of packaging machines, but because of the characteristics of fried foods and repeated tests, the packaging effect of the multi-head weigher packaging machine is better.

How Does Pork Rinds Packaging Machine Work?

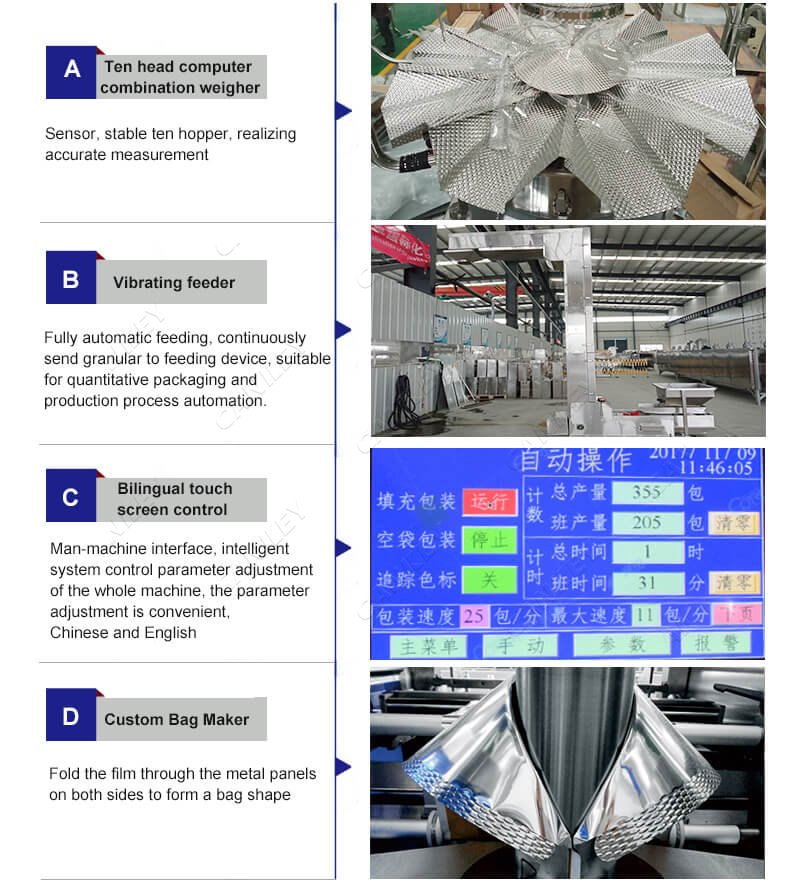

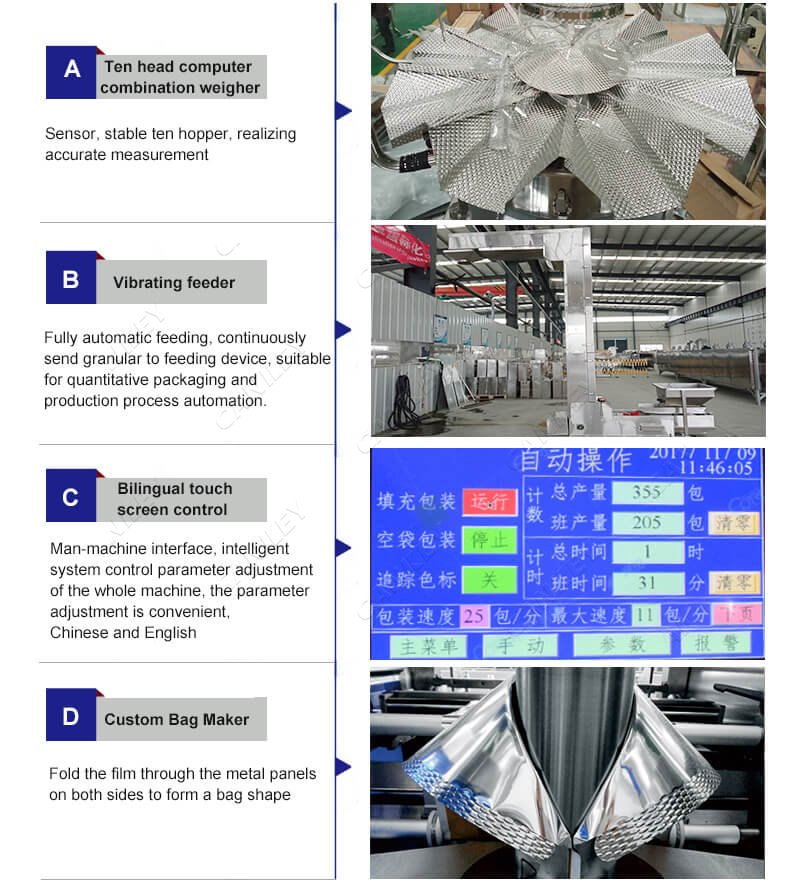

1. In the upper feeding hopper, the pork rinds is vibrated through the main vibrating plate, so that the material is distributed to the various linear vibrating plates on the conical funnel.

2. When there is no material or insufficient material in the line vibration plate, the photoelectric detection switch detects it and sends a feeding signal to the main board, and then sends a feeding signal to the material conveyor through the main board to start feeding.

3. The line vibration machine vibrates, drives the line vibration plate to vibrate, adjusts the appropriate amplitude and vibration time to send a certain range of material weight to each storage hopper.

4. The driving equipment is the stepping motor, and the door of the storage hopper is opened, and the materials are sent to the weighing hopper.

5. The pork rinds in the weighing hopper generates a weight signal through the sensor, and then transmits it to the main board of the control device through the lead wire. The CPU on the main board reads and records the weight of each weighing bucket, and then through calculation, analysis, and combination, the combination weighing bucket closest to the target weight is selected. When receiving the unloading request signal sent by the packaging machine, the CPU sends a signal to start the weighing hopper motor driver to open the selected weighing hopper and unload the product into the unloading chute into the packaging machine, and then complete the packaging process.

Onion Rings Packaging Machine Advantages:

❤ Mechanical automatic weighing, which is conducive to food safety.

❤ Fast weighing speed.

❤ High dynamic weighing accuracy.

❤ High degree of automation.

Why Is The Multi-head Combination Weigher Particularly Favored by Various Food Companies?

Using a combination weigher pork rinds packaging machine for quantitative weighing, compared with general prok rinds packaging machine, to complete the same workload: Combination packing machine requires 1 set, 2 operators, speed 60 bags/min, single bag error 0.3~0.5 grams, working 8 hours a day, total error about 14 kg. However, a general packing machine requires 5 sets, 10 operators, a speed of 12 bags/min, a single bag error of 3 grams, 8 hours of work per day, and a total error of 86 kg. Obviously, using a combination weigher packaging machine will save packaging costs.

Which Packaging Machine Is Better for Packaging Fried Pork Rinds/Onion Rings?

Generally, we will provide customers with different types of packaging machines, but because of the characteristics of fried foods and repeated tests, the packaging effect of the multi-head weigher packaging machine is better.

How Does Pork Rinds Packaging Machine Work?

1. In the upper feeding hopper, the pork rinds is vibrated through the main vibrating plate, so that the material is distributed to the various linear vibrating plates on the conical funnel.

2. When there is no material or insufficient material in the line vibration plate, the photoelectric detection switch detects it and sends a feeding signal to the main board, and then sends a feeding signal to the material conveyor through the main board to start feeding.

3. The line vibration machine vibrates, drives the line vibration plate to vibrate, adjusts the appropriate amplitude and vibration time to send a certain range of material weight to each storage hopper.

4. The driving equipment is the stepping motor, and the door of the storage hopper is opened, and the materials are sent to the weighing hopper.

5. The pork rinds in the weighing hopper generates a weight signal through the sensor, and then transmits it to the main board of the control device through the lead wire. The CPU on the main board reads and records the weight of each weighing bucket, and then through calculation, analysis, and combination, the combination weighing bucket closest to the target weight is selected. When receiving the unloading request signal sent by the packaging machine, the CPU sends a signal to start the weighing hopper motor driver to open the selected weighing hopper and unload the product into the unloading chute into the packaging machine, and then complete the packaging process.

Onion Rings Packaging Machine Advantages:

❤ Mechanical automatic weighing, which is conducive to food safety.

❤ Fast weighing speed.

❤ High dynamic weighing accuracy.

❤ High degree of automation.

Why Is The Multi-head Combination Weigher Particularly Favored by Various Food Companies?

Using a combination weigher pork rinds packaging machine for quantitative weighing, compared with general prok rinds packaging machine, to complete the same workload: Combination packing machine requires 1 set, 2 operators, speed 60 bags/min, single bag error 0.3~0.5 grams, working 8 hours a day, total error about 14 kg. However, a general packing machine requires 5 sets, 10 operators, a speed of 12 bags/min, a single bag error of 3 grams, 8 hours of work per day, and a total error of 86 kg. Obviously, using a combination weigher packaging machine will save packaging costs.

Technical Data

| Model | CK-LK420 |

| Film width | max 420mm |

| Bag width | 80-200mm |

| Bag length | 50-300mm |

| Packing speed | 15-80bags/min |

| Packing range | 150-1500ml |

| Film thickness | 0.04-0.10mm |

| Power | 2.5kw/220v 50-60Hz |

| Machine size | 1400*970*1700mm |

| Machine weight | 450kg |

| Air consumption | 0.4m³/min 0.6mpa |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price