Automatic Puff Snacks Packing Machine Price

Features

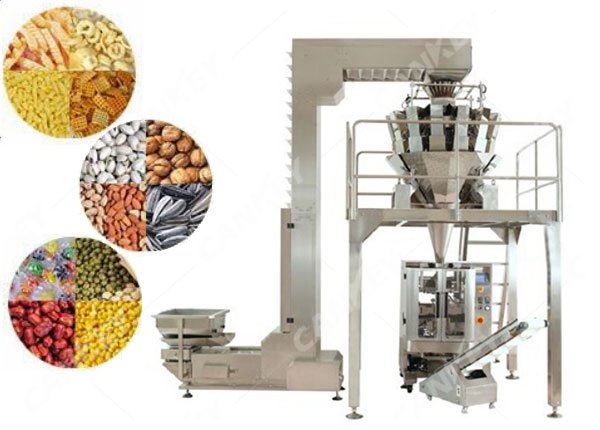

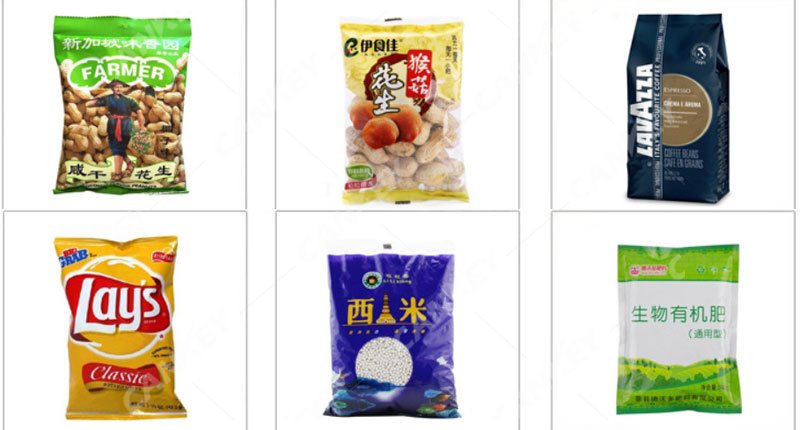

The automatic snacks packing machine adopts a new design, widely used for different types of snacks, such as puffed food, namkeen, kurkure, etc. And we promise the machine with factory price

Automatic Snacks Packing Machine Advantages:

1. More stable: The “stable time fixed development mode” is adopted to ensure the long-term stable operation of the combination scale and to achieve the core factor of material saving.

2. Multiple combinations of mode options: Digital and modular, single and multiple outlets, high precision and high speed.

3. High precision: The puff snacks packing machine through accurate calculation and control of the hopper motor rotation time, line vibration machine delay, line vibration machine action time and other indicators, the interference factors for reading weight values are avoided to the utmost.

4. Customizable: Customized services are provided according to the customer's materials to meet the individual needs of the customer.

Automatic Snacks Packing Machine Composition:

O Combination scale: The perfect combination of high precision and high speed, the best combination is instantly selected from a rich weight combination by computer calculation. According to the characteristics of the object to be measured, the opening and closing speed of the hopper door can be finely adjusted to prevent breakage and jamming. Powerful data automatic statistics function, record the total number of packages, pass rate and single bag error of each batch of production.

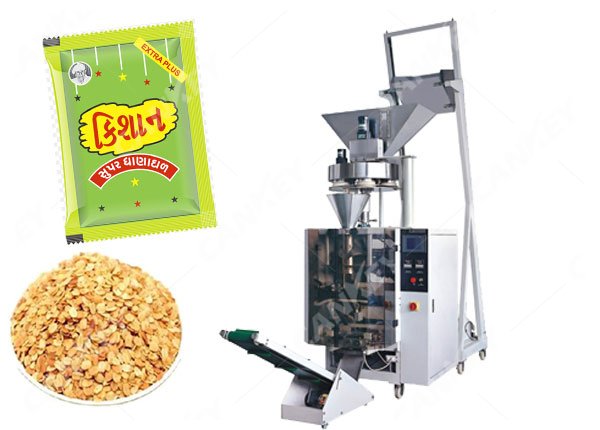

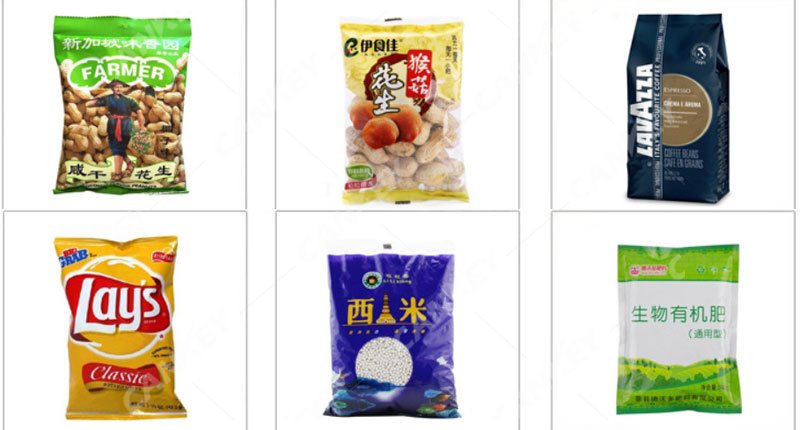

O Packing machine: The puff snacks packing machine is suitable for quantitative weighing of various granular, flake, strip and irregular shapes of candy, potato chips, Namkeen, kurkure, peanut, potato chips, puffed foods, etc.

O Z type hoist: The hoist is suitable for vertical lifting of food, feed and other materials. The hoist is driven by the chain drive to lift the hopper for vertical conveying of particles and small pieces of material, which has the advantages of large lifting capacity and high lifting degree.

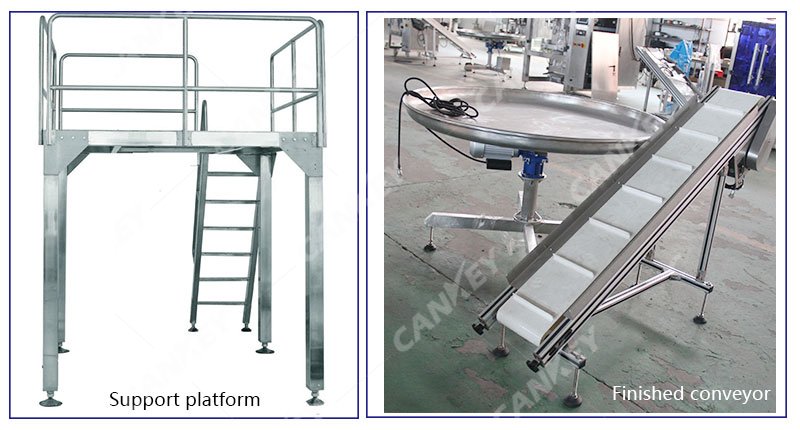

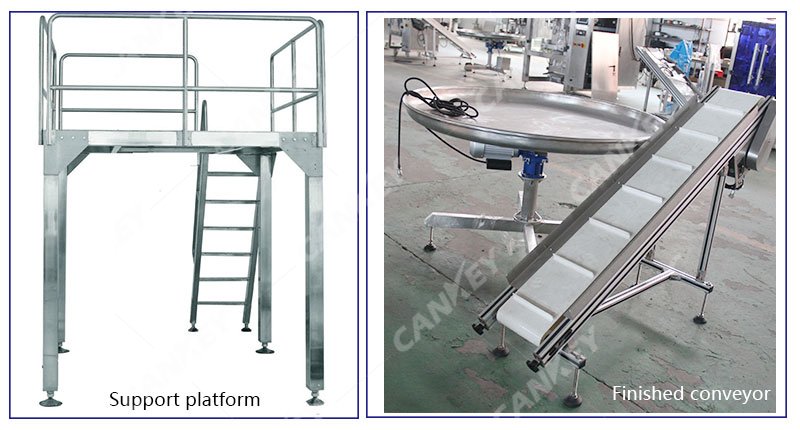

O Support platform: The platform is firm and not easy to shake, beautiful and generous, the countertop is made of non-slip pattern aluminum plate, and the surrounding fence is practical and safe.

O Finished conveyor: The machine can transport the packaged finished bag to the packaged inspection equipment or packaging platform.

Regarding the price of each component of the snacks packing machine, we will send to your email after receive your inquiry.

Automatic Snacks Packing Machine Advantages:

1. More stable: The “stable time fixed development mode” is adopted to ensure the long-term stable operation of the combination scale and to achieve the core factor of material saving.

2. Multiple combinations of mode options: Digital and modular, single and multiple outlets, high precision and high speed.

3. High precision: The puff snacks packing machine through accurate calculation and control of the hopper motor rotation time, line vibration machine delay, line vibration machine action time and other indicators, the interference factors for reading weight values are avoided to the utmost.

4. Customizable: Customized services are provided according to the customer's materials to meet the individual needs of the customer.

Automatic Snacks Packing Machine Composition:

O Combination scale: The perfect combination of high precision and high speed, the best combination is instantly selected from a rich weight combination by computer calculation. According to the characteristics of the object to be measured, the opening and closing speed of the hopper door can be finely adjusted to prevent breakage and jamming. Powerful data automatic statistics function, record the total number of packages, pass rate and single bag error of each batch of production.

O Packing machine: The puff snacks packing machine is suitable for quantitative weighing of various granular, flake, strip and irregular shapes of candy, potato chips, Namkeen, kurkure, peanut, potato chips, puffed foods, etc.

O Z type hoist: The hoist is suitable for vertical lifting of food, feed and other materials. The hoist is driven by the chain drive to lift the hopper for vertical conveying of particles and small pieces of material, which has the advantages of large lifting capacity and high lifting degree.

O Support platform: The platform is firm and not easy to shake, beautiful and generous, the countertop is made of non-slip pattern aluminum plate, and the surrounding fence is practical and safe.

O Finished conveyor: The machine can transport the packaged finished bag to the packaged inspection equipment or packaging platform.

Regarding the price of each component of the snacks packing machine, we will send to your email after receive your inquiry.

Technical Data

| Model | CK-420AZ |

| Air consumption | 2.5m3/min.6kg/cm2 |

| Max. Film width | Max.420mm |

| Bag length | 80-300mm |

| Bag width | 80-200mm |

| Max. film roll diameter | Max.360mm |

| Packaging speed | 5-60bags/min |

| Packing thickness | 0.04-0.08mm |

| Power supply specification | 220V.50/60Hz.2.4KVA |

| Dimension | (L)1100x(W)925x(H)1620mm |

| Packing machine weight | 850kg |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price