Biscuit Packaging Machine Sold to Bangalore

- Release Lime: Feb 07 2023

- Source: Sherry

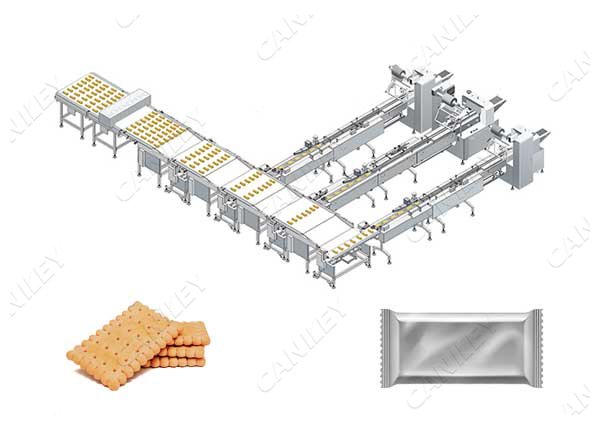

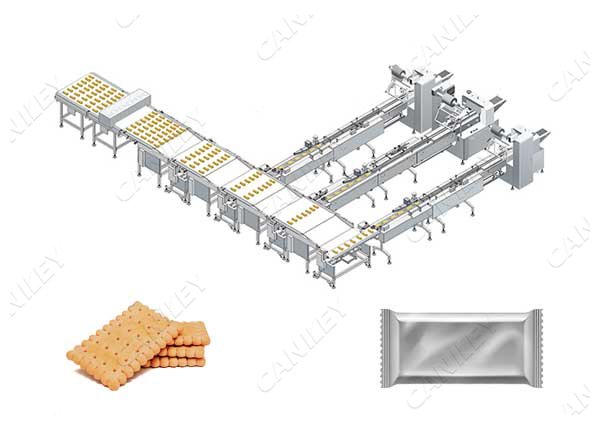

The biscuit packaging machine ordered by the Bangalore customer is currently in expedited production, because their new production line is about to be installed, and then the packaging line will be installed. In order to ensure that the production line can be put into production on schedule, our workers are expediting production and testing.

The Bangalore customer ordered an automatic packaging line consisting of 3 biscuit packaging machines. It can be connected with the front-end biscuit production equipment to build a modern biscuit production factory.

Work process:

The conveyor belt runs horizontally and pushes the product into the packaging material formed by the bag making machine. The middle sealing device heats and seals the bottom of the packaging material, and the end sealing device heats and seals the end of the packaging material, and the packaging material forms a long tube Cut into individual packages.

During the entire packaging process, the packaging machine needs the following three axes of action: feed conveyor shafts, packaging drive shafts and end seal shafts. The coordination between these three axes includes speed coordination, phase coordination, coordination between end seal meshing and packaging material running line speed, speed coordination adjustment, and phase coordination adjustment. Regardless of the traditional motor drive and frequency converter control mode or the servo drive mode, the above basic requirements must be met.

Machine advantages:

1. The overall design is standardized and integrated. Using a fully automatic packaging machine can realize the packaging of different products, just use the integrated design of the original model, quickly carry out specification and model replacement, or change to other packaging models in a short period of time.

2. Packaging is faster.

3. Runs with high precision. AC servo motor, computer control (NC), programmable logic controller PLC and other precision processing actuators are used to manipulate various shapes, so that the precision of the entire machine-made packaging bag is improved.

4. Intelligent system. Using well-known brand accessories, you can track and adjust various parameters of the machine through the intelligent control panel and the menu system on the touch screen.

The Bangalore customer ordered an automatic packaging line consisting of 3 biscuit packaging machines. It can be connected with the front-end biscuit production equipment to build a modern biscuit production factory.

Work process:

The conveyor belt runs horizontally and pushes the product into the packaging material formed by the bag making machine. The middle sealing device heats and seals the bottom of the packaging material, and the end sealing device heats and seals the end of the packaging material, and the packaging material forms a long tube Cut into individual packages.

During the entire packaging process, the packaging machine needs the following three axes of action: feed conveyor shafts, packaging drive shafts and end seal shafts. The coordination between these three axes includes speed coordination, phase coordination, coordination between end seal meshing and packaging material running line speed, speed coordination adjustment, and phase coordination adjustment. Regardless of the traditional motor drive and frequency converter control mode or the servo drive mode, the above basic requirements must be met.

Machine advantages:

1. The overall design is standardized and integrated. Using a fully automatic packaging machine can realize the packaging of different products, just use the integrated design of the original model, quickly carry out specification and model replacement, or change to other packaging models in a short period of time.

2. Packaging is faster.

3. Runs with high precision. AC servo motor, computer control (NC), programmable logic controller PLC and other precision processing actuators are used to manipulate various shapes, so that the precision of the entire machine-made packaging bag is improved.

4. Intelligent system. Using well-known brand accessories, you can track and adjust various parameters of the machine through the intelligent control panel and the menu system on the touch screen.

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Your Location:

Your Location: