Working Principle of Vertical Form Fill Seal Machine

- Release Lime: Apr 21 2021

- Source: Sherry

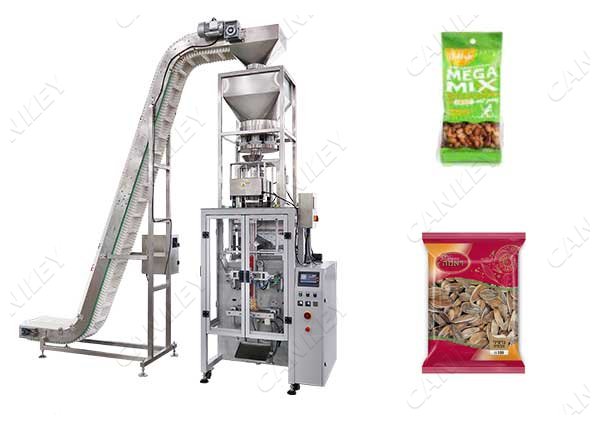

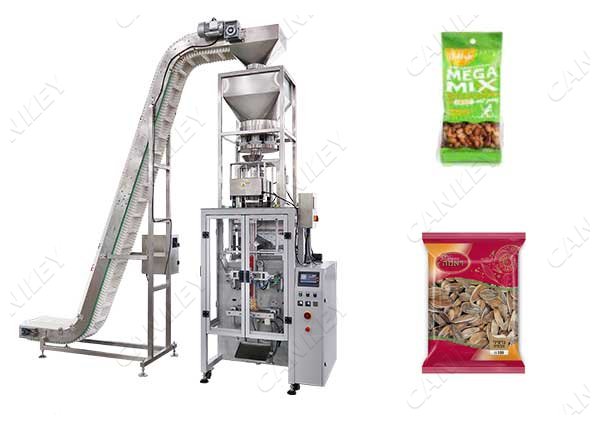

What is the working principle of vertical form fill seal machine? First, the packaging film is made into a bag, and then the bag is filled with materials and sealed for transportation. The VFFS machine can run at a very high speed, up to 70 bags per minute, and the bags are made of film roll, so its cost is lower than that of pre-made bags.

Main working principle:

Step 1 : Forming of a bag

The film is fed flat and tensioned to the filling tube, however the shape of the bag must be given to the packaging film in order to be able to perform the filling. It is done thanks to a specific part of the forming tube, called forming shoulder. The packaging film is then twisted around the forming tube and pulled all along the tube, which enables the next stages of the filling process.

Step 2 : Vertical sealing

Once the packaging film is well wrapped around the forming tube, then a first sealing, on the side, can be done. The forming collar and the width of the packaging reel must be such that there is an overlap when wrapping the material around the tube. A couple of sealing bars, is then used to press against each other the 2 parts of the overlapping material and weld them, often thanks to heating, to create a side seal.

Step 3 : Bottom sealing

It is done by another couple of sealing bars that are also welding the material through pressure and heating.The film is then pulled down by a length corresponding to the desired pouch length.

Step 4 : Product filling

The dosing system positioned about the forming tube can finally be run in order to dose the amount of product to dose. The material falling down through the forming tube and inside the open pouch being manufactured.

Step 5 : Top sealing

Once the dosing of product has been done, then the same sealing bars that performed the bottom seal are activated again to, this time, create the top seal and close the pouch.

Stpe 6 : Cutting and discharge

After close the bag, it is then cut and falls down to a collection system, typically a belt conveyor that brings the pouch to the next packaging step.(cartoning or others)

But for different models of machines, the working principle may be different, if you need more information, please contact us info@cankeytech.com

Main working principle:

Step 1 : Forming of a bag

The film is fed flat and tensioned to the filling tube, however the shape of the bag must be given to the packaging film in order to be able to perform the filling. It is done thanks to a specific part of the forming tube, called forming shoulder. The packaging film is then twisted around the forming tube and pulled all along the tube, which enables the next stages of the filling process.

Step 2 : Vertical sealing

Once the packaging film is well wrapped around the forming tube, then a first sealing, on the side, can be done. The forming collar and the width of the packaging reel must be such that there is an overlap when wrapping the material around the tube. A couple of sealing bars, is then used to press against each other the 2 parts of the overlapping material and weld them, often thanks to heating, to create a side seal.

Step 3 : Bottom sealing

It is done by another couple of sealing bars that are also welding the material through pressure and heating.The film is then pulled down by a length corresponding to the desired pouch length.

Step 4 : Product filling

The dosing system positioned about the forming tube can finally be run in order to dose the amount of product to dose. The material falling down through the forming tube and inside the open pouch being manufactured.

Step 5 : Top sealing

Once the dosing of product has been done, then the same sealing bars that performed the bottom seal are activated again to, this time, create the top seal and close the pouch.

Stpe 6 : Cutting and discharge

After close the bag, it is then cut and falls down to a collection system, typically a belt conveyor that brings the pouch to the next packaging step.(cartoning or others)

But for different models of machines, the working principle may be different, if you need more information, please contact us info@cankeytech.com

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Your Location:

Your Location: