Multi Lane Automatic Honey Stick Packaging Machine

Features

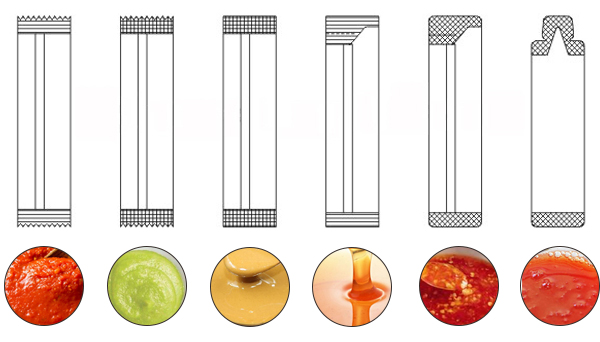

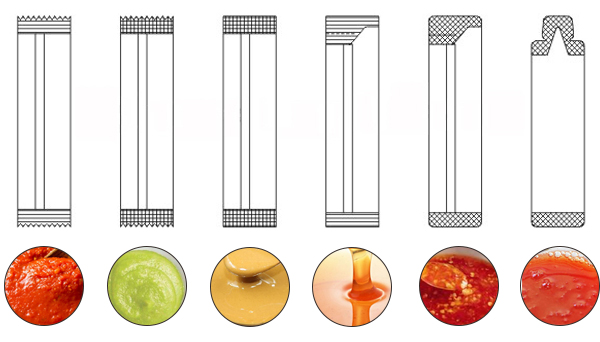

Application:

Multi Lane Packaging Machine is suitable for many kinds of liquid products, such as ketchup, honey, gel, sauce, oil, paste, ice candy, etc. Ideal for food or diet products, personal care applications, confectionaries, pharmaceuticals and more.

How Does the Multi Lane Packaging Machine Work?

There are 6 main steps:

1. Film transport & unwinding

2. Film tension

3. Film cutting

4. Stick pack forming

5. Filling and sealing

6. Stick pack discharge

Automatic Honey Stick Machine Features:

❤ Automatic split film at right position, liquid measuring and filling, multi lanes bag forming, cutting, sensor tracking, counting capacity.

❤ High precision photocell sensor for auto tracking the eye mark printing on the film, so cut each bag at precisely position.

❤ The multi lane packaging machine uses PLC controller, high function and control the whole machine’s work steps.

❤ Using optical tracking system to ensure that the bags automatic two-sided version of the pattern, and with automatic counting function.

❤ Adaptable to packaging materials, the honey stick machine has an automatic sealing temperature control function, and high control accuracy. Can be adapted to a variety of domestic and foreign production of packaging films, such as PET / AL / PE, PET / PE, NY / AL / PE, NY / PE and so on.

Ancillary Equipment:

Some ancillary equipment for the stick pack machine enables automation from raw material to pallet. Examples include packs counting using a chute with a trap gate and takeaway conveyors that count into a carton and printing options that can print a use-by date and lot number on each stick.

Multi Lane Packaging Machine is suitable for many kinds of liquid products, such as ketchup, honey, gel, sauce, oil, paste, ice candy, etc. Ideal for food or diet products, personal care applications, confectionaries, pharmaceuticals and more.

How Does the Multi Lane Packaging Machine Work?

There are 6 main steps:

1. Film transport & unwinding

2. Film tension

3. Film cutting

4. Stick pack forming

5. Filling and sealing

6. Stick pack discharge

Automatic Honey Stick Machine Features:

❤ Automatic split film at right position, liquid measuring and filling, multi lanes bag forming, cutting, sensor tracking, counting capacity.

❤ High precision photocell sensor for auto tracking the eye mark printing on the film, so cut each bag at precisely position.

❤ The multi lane packaging machine uses PLC controller, high function and control the whole machine’s work steps.

❤ Using optical tracking system to ensure that the bags automatic two-sided version of the pattern, and with automatic counting function.

❤ Adaptable to packaging materials, the honey stick machine has an automatic sealing temperature control function, and high control accuracy. Can be adapted to a variety of domestic and foreign production of packaging films, such as PET / AL / PE, PET / PE, NY / AL / PE, NY / PE and so on.

Ancillary Equipment:

Some ancillary equipment for the stick pack machine enables automation from raw material to pallet. Examples include packs counting using a chute with a trap gate and takeaway conveyors that count into a carton and printing options that can print a use-by date and lot number on each stick.

Technical Data

| Model | CK-280BY-4 |

| Voltage |

220V,50Hz,single phase (could be customized) |

| Power | 3.5kw |

| Packing list number | 4 |

| Packing speed | Single column Max. 35 packs/min |

| Packaging size | Length: 50-180mm width: 17-30mm |

| Film width | Maximum 280 mm |

| film thickness | 0.05-0.1mm |

| Dimension | 1385*918*2005mm |

| Weight | 350kg |

| Materials | 304 stainless steel |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price