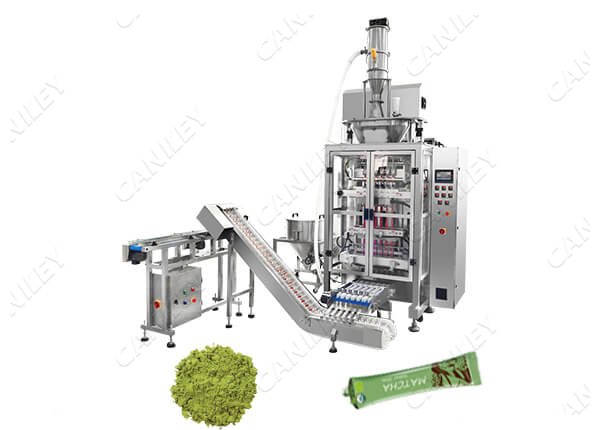

Fully Automatic Matcha Powder Packing Machine Back Seal

Features

The matcha powder packing machine is developed according to customers' requirements for high-speed packaging. It is suitable for fully automatic packing of powder materials in the industries of food, medicine and health products. Such as: herb powder, protein powder, milk powder, tea powder, probiotics, maca powder, coffee powder, milk powder, juice powder, chocolate powder, etc.

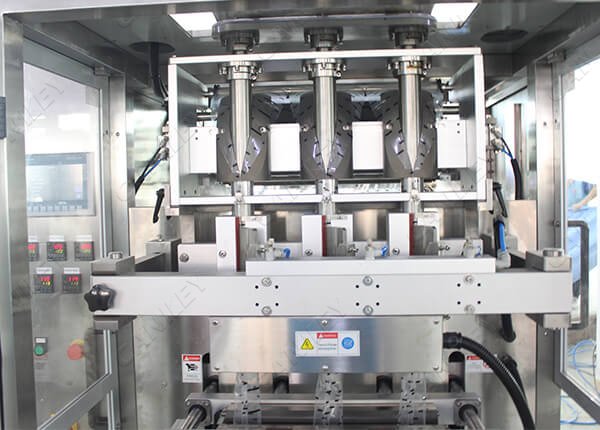

☆ The longitudinal sealing mechanism adopts a 45-degree inclined remote longitudinal sealing design.

☆ The punching mechanism adopts independent double easy tearing design, easy to adjust and replace.

☆ The horizontal sealing mechanism adopts high-precision servo control and special mold treatment, which is more wear-resistant.

☆ The cutting mechanism adopts a modular design, and the tool material has been specially treated, which is more wear-resistant.

☆ The film frame mechanism adopts automatic deviation correction and automatic balance tension control, which is suitable for a wider range of packaging film.

A. New European and American standard design, stainless steel 304 is used for the part in contact with the matcha powder.

B. Taking into account the characteristics and measurement accuracy of matcha powder, the measurement method adopts the screw measurement method, which is convenient and accurate.

C. The fully automatic powder packing machine can be equipped with a dust absorption device to ensure a clean packaging environment and at the same time ensure the sealing effect of the pouch.

D. You can increase the ribbon to print the production batch number and date.

E. The packaging film has no waste edges, which reduces the waste of packaging film and reduces production costs.

Convenience:

A. PLC automatic control, touch screen operation, and humanized control interface make operation and parameter setting simple and quick, and have error prompts and self-diagnosis functions.

B. The length of the packaging bag can be adjusted online through the touch screen.

C. The matcha powder packing machine is equipped with a cursor marking device to ensure that the pattern on the bag is stable at the set position.

D. When the packaging film is used up, it will automatically shut down and alarm (the screen will display the cause of the alarm).

E. The matcha powder bag sealing adopts the principle of heating and pressing, the heating temperature of the horizontal and vertical sealing is independently adjustable, the temperature is displayed in real time, and the sealing temperature can be adjusted according to different packaging film.

F. The touch screen visually displays the number of qualified products in the shift and the total output of the shift.

Safety:

First of all, the automaticmatcha powder packing machine is equipped with a safety door, and the machine will automatically stop (set) when the safety door is opened; standard safety switch; in line with EU CE safety standards. In addition, an emergency stop button is installed on the machine to ensure the personal safety of the operator.

Simple maintenance:

The model has simple structure design, low failure rate, few wearing parts and convenient maintenance.

Easy to clean:

New European and American design, open electrical box, cleaning and maintenance are more convenient and time-saving. All parts in contact with the matcha powder to be packaged can be quickly disassembled and installed quickly, and it is very convenient to scrub.

How Does Fully Automatic Powder Packing Machine Work?

Install the packaging film roll on the machine, after dividing the film on the designated row, they are made into cylindrical bags. And at the same time, it is intermittently automatically metered and filled. The operation is simple and reliable, and the bag length and bag width can be adjusted. Different bag shapes can be made, such as three-side seal, four-side seal, back seal, special-shaped bag, etc.Matcha Powder Packing Machine Structural Features:

☆ According to the mesh of matcha powder, the silo has a variety of solutions to suit the packaging of matcha powder in different states. Ensure that the seal is clean and no material clamping.☆ The longitudinal sealing mechanism adopts a 45-degree inclined remote longitudinal sealing design.

☆ The punching mechanism adopts independent double easy tearing design, easy to adjust and replace.

☆ The horizontal sealing mechanism adopts high-precision servo control and special mold treatment, which is more wear-resistant.

☆ The cutting mechanism adopts a modular design, and the tool material has been specially treated, which is more wear-resistant.

☆ The film frame mechanism adopts automatic deviation correction and automatic balance tension control, which is suitable for a wider range of packaging film.

Matcha Powder Packing Machine Characteristic:

Practicality:A. New European and American standard design, stainless steel 304 is used for the part in contact with the matcha powder.

B. Taking into account the characteristics and measurement accuracy of matcha powder, the measurement method adopts the screw measurement method, which is convenient and accurate.

C. The fully automatic powder packing machine can be equipped with a dust absorption device to ensure a clean packaging environment and at the same time ensure the sealing effect of the pouch.

D. You can increase the ribbon to print the production batch number and date.

E. The packaging film has no waste edges, which reduces the waste of packaging film and reduces production costs.

Convenience:

A. PLC automatic control, touch screen operation, and humanized control interface make operation and parameter setting simple and quick, and have error prompts and self-diagnosis functions.

B. The length of the packaging bag can be adjusted online through the touch screen.

C. The matcha powder packing machine is equipped with a cursor marking device to ensure that the pattern on the bag is stable at the set position.

D. When the packaging film is used up, it will automatically shut down and alarm (the screen will display the cause of the alarm).

E. The matcha powder bag sealing adopts the principle of heating and pressing, the heating temperature of the horizontal and vertical sealing is independently adjustable, the temperature is displayed in real time, and the sealing temperature can be adjusted according to different packaging film.

F. The touch screen visually displays the number of qualified products in the shift and the total output of the shift.

Safety:

First of all, the automaticmatcha powder packing machine is equipped with a safety door, and the machine will automatically stop (set) when the safety door is opened; standard safety switch; in line with EU CE safety standards. In addition, an emergency stop button is installed on the machine to ensure the personal safety of the operator.

Simple maintenance:

The model has simple structure design, low failure rate, few wearing parts and convenient maintenance.

Easy to clean:

New European and American design, open electrical box, cleaning and maintenance are more convenient and time-saving. All parts in contact with the matcha powder to be packaged can be quickly disassembled and installed quickly, and it is very convenient to scrub.

Technical Data

| Model | CKMLPF-800-06P |

| Package material thickness: | 0.04-0.08 mm |

| Bag length range: | 50mm-120mm |

| Bag width range: | 40-100mm |

| Sealing width: | 4-15mm |

| Packing speed: | 20-45 times / Min |

| Gas source: | 0.6-0.8Mpa |

| Power supply specification: | 220V/380V 50/60HZ |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price