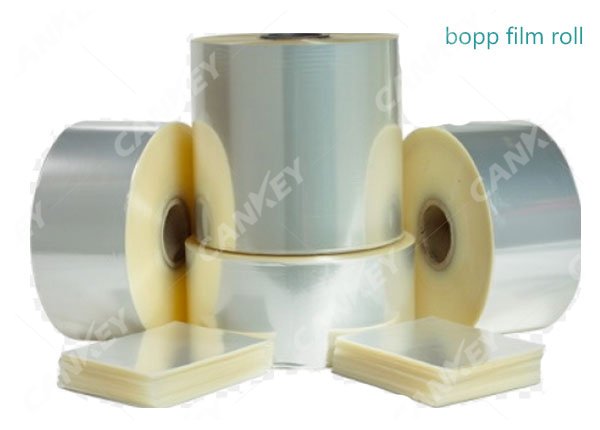

Heat Sealable BOPP Film/BOPP Film Roll Manufacturers

Features

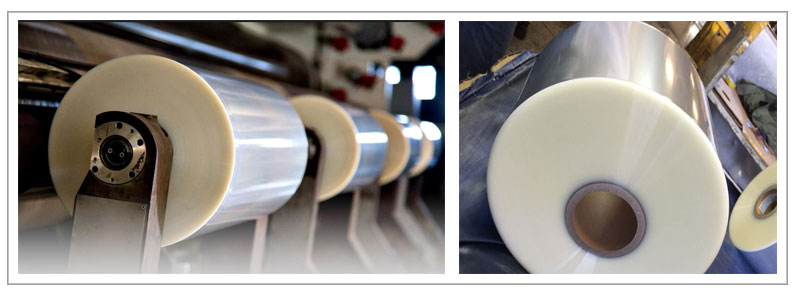

Heat sealable BOPP film is a kind of high-performance packaging film, which adopts special processing technology and has asymmetric design with different properties on both sides. The BOPP film can better adapt to high speed, low speed operation, low static, high transparency, high gloss, can better wrap the product, the packaging effect is smooth to achieve a more beautiful effect.

Heat Sealable BOPP Film Features:

◎ With high transparency and gloss, non-toxic materials, stable molecular structure, odor and moisture have a certain barrier function, is the ideal packaging materials for cigarettes, drugs, health products, food and other products.

◎ These BOPP film rolls have the density nearer to 0.90 g/m and hence it renders high yield at the same cost as compared to other films viz. polyester films.

◎ Heat sealable BOPP film with excellent gloss and high transparency, so that it has an excellent appearance and fine finish, BOPP film with good moisture resistance, but also can resist pollution and harmful chemicals.

◎ Low static, very clear, with the best dimensional stability and flatness.

◎ The BOPP film rolls have good puncture resistance and bending crack resistance in the temperature range.

◎ Heat sealable BOPP films are not affected by moisture and do not wrinkle or shrink with environmental changes. They are recyclable.

Heat Sealable BOPP Film Advantage:

〇 They are environmentally friendly.

〇 It is easily accepted all over the world.

〇 Due to transportation, weather and other reasons caused by the product damage less.

〇 BOPP film can keep the product dry.

〇 No layers required, good transparency and uv resistance.

As a BOPP film manufacturer, we also produce different types of the packaging film. And can custom according to customers’ requirement.

Heat Sealable BOPP Film Features:

◎ With high transparency and gloss, non-toxic materials, stable molecular structure, odor and moisture have a certain barrier function, is the ideal packaging materials for cigarettes, drugs, health products, food and other products.

◎ These BOPP film rolls have the density nearer to 0.90 g/m and hence it renders high yield at the same cost as compared to other films viz. polyester films.

◎ Heat sealable BOPP film with excellent gloss and high transparency, so that it has an excellent appearance and fine finish, BOPP film with good moisture resistance, but also can resist pollution and harmful chemicals.

◎ Low static, very clear, with the best dimensional stability and flatness.

◎ The BOPP film rolls have good puncture resistance and bending crack resistance in the temperature range.

◎ Heat sealable BOPP films are not affected by moisture and do not wrinkle or shrink with environmental changes. They are recyclable.

Heat Sealable BOPP Film Advantage:

〇 They are environmentally friendly.

〇 It is easily accepted all over the world.

〇 Due to transportation, weather and other reasons caused by the product damage less.

〇 BOPP film can keep the product dry.

〇 No layers required, good transparency and uv resistance.

As a BOPP film manufacturer, we also produce different types of the packaging film. And can custom according to customers’ requirement.

Technical Data

| Density | 0.905g/cm3 |

| Common thickness | 18μ,19μ,20μ, 38μ,40μ |

| Moisture permeability | 4-10 (g/24h'm2, 25μm, 30°C, 90%RH) |

| Oxygen permeability | 2400 ( cm3/24h'm25μm, 23°C, 0%RH) |

| Tensile strength | 1300-2000(Kgf/cm) |

| Tear strength | 4-6(gf/25cm) |

| Softening temperature | 130-150°C |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price