Cosmetic Shrink Wrap Chamber Machine Commercial Use

Features

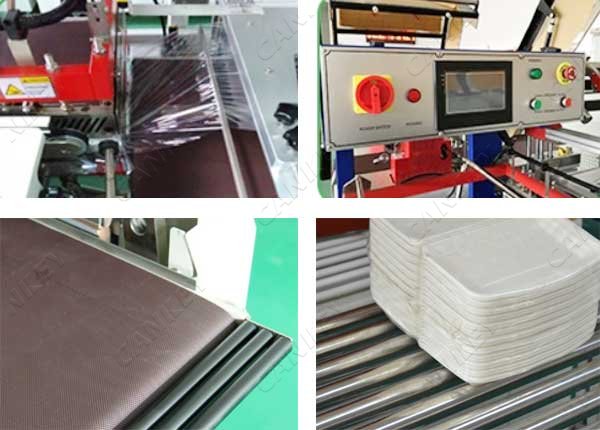

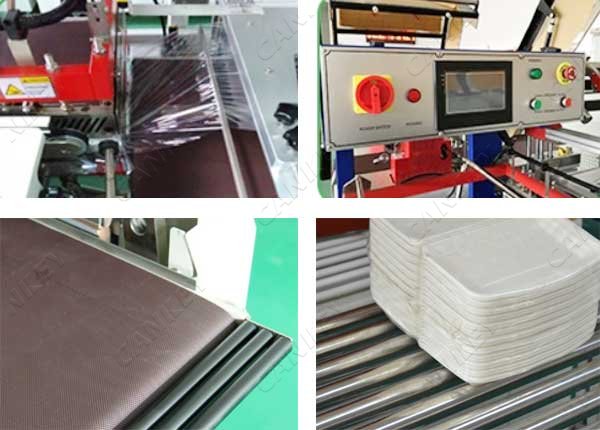

This cosmetic shrink wrap machine wraps the shrink film on the outside of the cosmetic. After heating, the film shrinks and clings to the surface of the cosmetic.

The shrink wrap chamber machine makes cosmetic fully display the appearance, to increase its aesthetics and value. At the same time, the wrapped cosmetic can be sealed and moisture-proof. The purpose of preventing pollution and damage.

Cosmetic Shrink Wrap Machine Working Principle:

Heat is generated by the quartz heating tube inside the furnace chamber, and the heating furnace chamber is filled with hot air of uniform temperature with the cooperation of the internal fan. The temperature in the furnace is controlled by a temperature control instrument and maintained at a constant temperature.

The cosmetic are sent into the shrinking furnace through a chain conveyor, and the heat shrinkable film shrinks at a high level. With the strong cold wind at the outlet, the shrinking film quickly adheres to the surface of the article.

Shrink Wrap Chamber Machine Features:

〇 The machine uses glass fiber sipe, anti-adhesive, high temperature resistant nickel-chromium alloy sealing cutter, the sealing is neat, does not crack, and does not burn.

〇 The cosmetic shrink wrap machine can work continuously for a long time without overheating the surrounding environment.

〇 Optimize the circuit design, control the temperature of the instrument, stop heating after the temperature reaches the set temperature, save power.

〇 Low power consumption, average power consumption is only 2.5KW per hour.

〇 The cosmetic shrink wrap machine uses high-power DC motor, stepless speed regulation, continuous work for a long time, and stable and reliable operation.

〇 All electrical parts are made of high-quality brands, and the quality of the shrink wrap chamber machine is effectively guaranteed.

〇 Two types of conveyor belts, chain and chain net, are available to meet the packaging needs of different products.

The shrink wrap chamber machine makes cosmetic fully display the appearance, to increase its aesthetics and value. At the same time, the wrapped cosmetic can be sealed and moisture-proof. The purpose of preventing pollution and damage.

Cosmetic Shrink Wrap Machine Working Principle:

Heat is generated by the quartz heating tube inside the furnace chamber, and the heating furnace chamber is filled with hot air of uniform temperature with the cooperation of the internal fan. The temperature in the furnace is controlled by a temperature control instrument and maintained at a constant temperature.

The cosmetic are sent into the shrinking furnace through a chain conveyor, and the heat shrinkable film shrinks at a high level. With the strong cold wind at the outlet, the shrinking film quickly adheres to the surface of the article.

Shrink Wrap Chamber Machine Features:

〇 The machine uses glass fiber sipe, anti-adhesive, high temperature resistant nickel-chromium alloy sealing cutter, the sealing is neat, does not crack, and does not burn.

〇 The cosmetic shrink wrap machine can work continuously for a long time without overheating the surrounding environment.

〇 Optimize the circuit design, control the temperature of the instrument, stop heating after the temperature reaches the set temperature, save power.

〇 Low power consumption, average power consumption is only 2.5KW per hour.

〇 The cosmetic shrink wrap machine uses high-power DC motor, stepless speed regulation, continuous work for a long time, and stable and reliable operation.

〇 All electrical parts are made of high-quality brands, and the quality of the shrink wrap chamber machine is effectively guaranteed.

〇 Two types of conveyor belts, chain and chain net, are available to meet the packaging needs of different products.

Technical Data

sealing and cutting:

heating tunnel:

| Model | CK-FL550 | |

| Power(KW) | 2.2 | |

| Voltage | AC220V/50/60HZ | |

| Max Packing Size L*W(MM) | 650*550 | |

| Max Sealing Size(MM) | <600 | |

| Packing Speed(bag/min) | 15-30 | |

| Gas Source | 6-8Kg/cm^2 | |

| Shrink Film | POF/PE | |

| Machine Size | 1750*900*1450 | |

| Weight | 350 | |

| Model | CK-BS5530N |

| Voltage | 220-380V/50-60HZ 3Phas |

| Power(KW) | 14 |

| Load(KG) | 30 |

| Heat Tunnel Size(mm) | 1500*550*300 |

| Machine Size(mm) | 1900*820*1400 |

| Transfer Speed(m/s) | 0-10 |

| Weight(KG) | 140 |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price