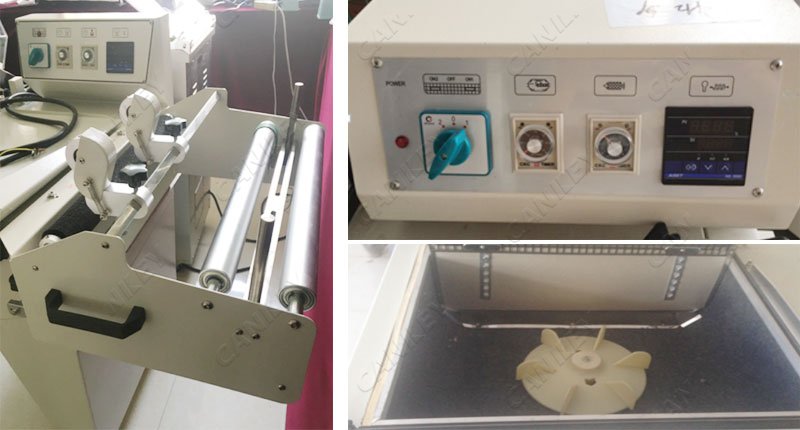

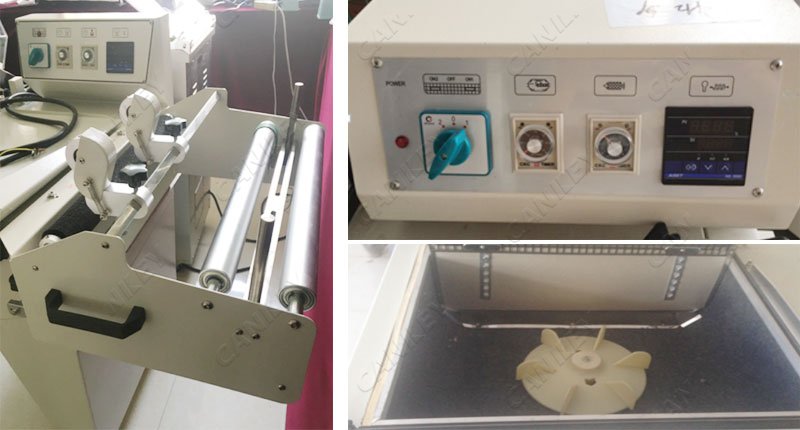

Manual Bottle Shrink Wrap Machine Small Size

Features

This manual bottle shrink wrap machine is based on widely absorbing the advantages of similar products at home and abroad. Widely used for pet bottles, glass bottles, cup noodles, milk bottles, water bottles, etc.

Principle of Manual Shrink Wrap Machine:

Its working principle is very simple, including the process of wrapping and shrinking. The wrapping process is that the items are first wrapped and sealed on the sealing and cutting machine, and then placed on the conveyor network to automatically enter the shrinking tunnel. The shrink packaging process is completed by tightly bonding the shrink film and the packaged items into one.

Manual Shrink Wrapping Machine Features:

〇 The shrink wrap tunnel is galvanized mesh conveyor belt, suitable for PE, POF, PVC and other kinds of thermal shrink film.

〇 The shrinking tunnel has an air-conditioned inner circulation duct design and a powerful turbine rotor. The shrink film can be uniformly heated in all directions, and the “expansion-exhaust-shrinkage” is completed in an instant to achieve perfect packaging effect.

〇 The small shrink wrap machine uses heat insulation fiberboard and unique internal circulation system, specially made seamless stainless steel electric heat pipe heating up quickly and evenly, PID automatic temperature control, electricity consumption is only 50% of similar China shrink wrap machines.

〇 The roller bar conveyor with rotation function can completely avoid hot stamping on the bottom of the package.

〇 Durable, for special products can also choose teflon mesh belt transport.

〇 The air duct inside shrinkage tunnel can be adjusted according to different shapes of packaging.

〇 The manual shrink wrapping machine can be customized according to customer requirements and product size.

Points to Note:

1. In the operation of manual shrink wrapping machine, if yoi found abnormal, should immediately stop inspection. After troubleshooting, can continue to use; If the fault cannot be eliminated, the operator should report to the management department in time.

2. After using this manual bottle shrink wrap machine, the three sets of heating switches should be turned off first, and the conveying motor and fan should continue running for about 10 minutes before the power is cut off.

Related Product:

Automatic Bottle Shrink Wrap Machine

Principle of Manual Shrink Wrap Machine:

Its working principle is very simple, including the process of wrapping and shrinking. The wrapping process is that the items are first wrapped and sealed on the sealing and cutting machine, and then placed on the conveyor network to automatically enter the shrinking tunnel. The shrink packaging process is completed by tightly bonding the shrink film and the packaged items into one.

Manual Shrink Wrapping Machine Features:

〇 The shrink wrap tunnel is galvanized mesh conveyor belt, suitable for PE, POF, PVC and other kinds of thermal shrink film.

〇 The shrinking tunnel has an air-conditioned inner circulation duct design and a powerful turbine rotor. The shrink film can be uniformly heated in all directions, and the “expansion-exhaust-shrinkage” is completed in an instant to achieve perfect packaging effect.

〇 The small shrink wrap machine uses heat insulation fiberboard and unique internal circulation system, specially made seamless stainless steel electric heat pipe heating up quickly and evenly, PID automatic temperature control, electricity consumption is only 50% of similar China shrink wrap machines.

〇 The roller bar conveyor with rotation function can completely avoid hot stamping on the bottom of the package.

〇 Durable, for special products can also choose teflon mesh belt transport.

〇 The air duct inside shrinkage tunnel can be adjusted according to different shapes of packaging.

〇 The manual shrink wrapping machine can be customized according to customer requirements and product size.

Points to Note:

1. In the operation of manual shrink wrapping machine, if yoi found abnormal, should immediately stop inspection. After troubleshooting, can continue to use; If the fault cannot be eliminated, the operator should report to the management department in time.

2. After using this manual bottle shrink wrap machine, the three sets of heating switches should be turned off first, and the conveying motor and fan should continue running for about 10 minutes before the power is cut off.

Related Product:

Automatic Bottle Shrink Wrap Machine

Technical Data

| Model | CK-FM5540 |

| Voltage | 220-240V / 50-60Hz |

| power | 3.8KW |

| Max. packing dimension (L*W*H) | 550*400*300mm |

| capacity | 500pcs/h |

| Machine size (L*W*H) | 1400*730*1450mm |

| Machine weight | 128kg |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price