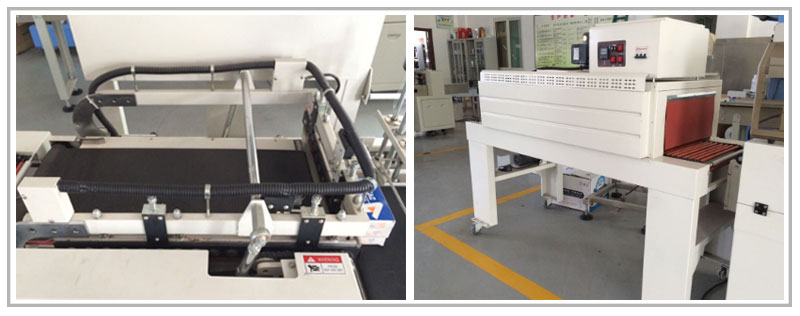

380V Commercial Soap Shrink Wrap Machine

Features

This soap shrink wrap machine can be used for shrink packaging different types of soap, including bar soap, round soap, etc.

Soap Shrink Wrap Machine Working Principle:

The commercial shrink wrap machine is wrapped with shrink film and then heated, so that the film shrinks and wraps the soap tightly. When the shrink film is heated, the irregular arrangement between the original molecules has changed. Under the thermal radiation such as infrared rays, the plastic molecules are re-arranged closely, so that the original area is greatly reduced, and the plastic molecules are attached to the surface of the soap to achieve the purpose of shrink packaging.

Features of Soap Shrink Wrap Machine:

◎ The commercial shrink wrap machine has the function of automatic feeding, film wrapping, sealing and cutting, shrinkage, cooling and finalizing.

◎ The world's advanced film thermostatic heat sealing technology, clear seal, firm.

◎ Unique shrinkage tunnel, two sets of centrifugal hot air circulation system, uniform heat balance, shrink tight and beautiful.

◎ The shrink wrap tunnel machine adopts linear feeding, and the length of the package is not limited (the height and width are customized according to customer requirements).

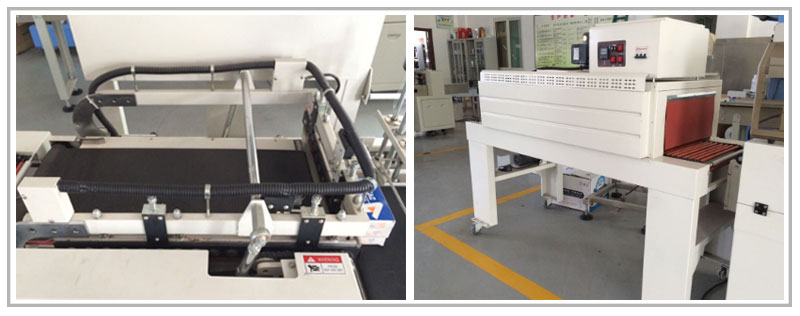

◎ Specially designed sealing knife, the sealing line is firm, no cracking, not easy to stick.

◎ The back end of the soap shrink wrap machine is equipped with a pressing device at the time of sealing and cutting, and prevents displacement for lighter items.

Commercial Shrink Wrap Machine Technical Characteristic:

1. Automatic sealing and cutting, automatic detection of products and inspection of product length.

2. Color touch screen, PLC operating system.

3. Applicable shrink film: PE, POF, folded film 10-50μ thick.

Shrink Wrap Tunnel Machine Optional Device:

〇 Printed film color code tracking photoelectric system.

〇 Feed or discharge belt conveyor.

Because different customers have different packaging requirements for soap, we also provide different machines to meet the requirements. Soap cellophane wrapping machine is another more popular equipment.

Soap Shrink Wrap Machine Working Principle:

The commercial shrink wrap machine is wrapped with shrink film and then heated, so that the film shrinks and wraps the soap tightly. When the shrink film is heated, the irregular arrangement between the original molecules has changed. Under the thermal radiation such as infrared rays, the plastic molecules are re-arranged closely, so that the original area is greatly reduced, and the plastic molecules are attached to the surface of the soap to achieve the purpose of shrink packaging.

Features of Soap Shrink Wrap Machine:

◎ The commercial shrink wrap machine has the function of automatic feeding, film wrapping, sealing and cutting, shrinkage, cooling and finalizing.

◎ The world's advanced film thermostatic heat sealing technology, clear seal, firm.

◎ Unique shrinkage tunnel, two sets of centrifugal hot air circulation system, uniform heat balance, shrink tight and beautiful.

◎ The shrink wrap tunnel machine adopts linear feeding, and the length of the package is not limited (the height and width are customized according to customer requirements).

◎ Specially designed sealing knife, the sealing line is firm, no cracking, not easy to stick.

◎ The back end of the soap shrink wrap machine is equipped with a pressing device at the time of sealing and cutting, and prevents displacement for lighter items.

Commercial Shrink Wrap Machine Technical Characteristic:

1. Automatic sealing and cutting, automatic detection of products and inspection of product length.

2. Color touch screen, PLC operating system.

3. Applicable shrink film: PE, POF, folded film 10-50μ thick.

Shrink Wrap Tunnel Machine Optional Device:

〇 Printed film color code tracking photoelectric system.

〇 Feed or discharge belt conveyor.

Because different customers have different packaging requirements for soap, we also provide different machines to meet the requirements. Soap cellophane wrapping machine is another more popular equipment.

Technical Data

| Model | CK-FL450 |

| Power | 380V/50-60Hz/3phase |

| Packaging Speed | 15 - 35 packs/min |

| Size of l-type sealing cutter | 570x480 mm |

| Packing height | 150 mm |

| Package Size | Width + height< 400mm, Length + height < 480mm |

| Packing Materials | POF,PE, Folded film |

| Maximum Film | 530mm (width ) x 280mm(Outer diameter) |

| Furnace Size | 1200(L) x 450(W) x 220(H) mm |

| Total Power | 8.5 kW |

| Platform Height | 780-850 mm |

| Pressure | 0.5MPa (5 bar) |

| Dimensions | 1600 x 770 x 1450mm 1600 x 600 x 1260mm |

| Weight | 450kgs |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price