CE Certification Disinfectant Wipes Making Machine Manufacturer

Features

This disinfectant wipes making machine is mainly used to produce small package wet wipes, wet tissues. Such as: make-up remover wipes, medical disinfection wipes, isopropanol wipes and lens wipe wipes, aviation wet wipes, etc.

Disinfectant Wipes Manufacturing Process:

Non-woven folding-- add liquid-- cutting-- feeding into bag-- sealing --print date-- add easy to tear-- finished disinfectant wipes output

Disinfectant Wipes Machine Features:

O The machine has strong continuity and stability, and can work continuously for 24 hours.

O Using well-known brand metering pump, accurate control (dosing error is 0.01ml/time).

O Simple and easy to control, servo motor, PLC touch screen, temperature, speed and length of disinfectant wipes can be adjusted freely.

O The disinfectant wipes making machine added film release device, dust-free cover, hygienic and easy to clean.

O Round corner right angle no waste device, free switching, no waste, simple and fast

O The roller traction structure is adopted, and the operation is more stable.

O 90-degree automatic finished product output mechanism, making finished products smoother and more beautiful.

O Optical and electrical integration design, automatic fault alarm, safety control instructions.

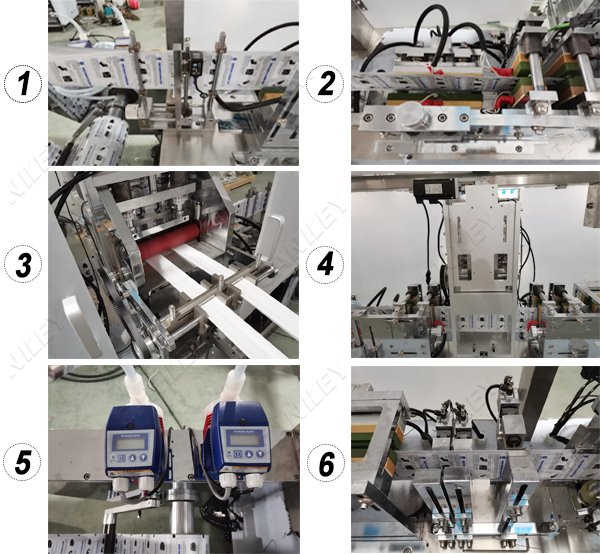

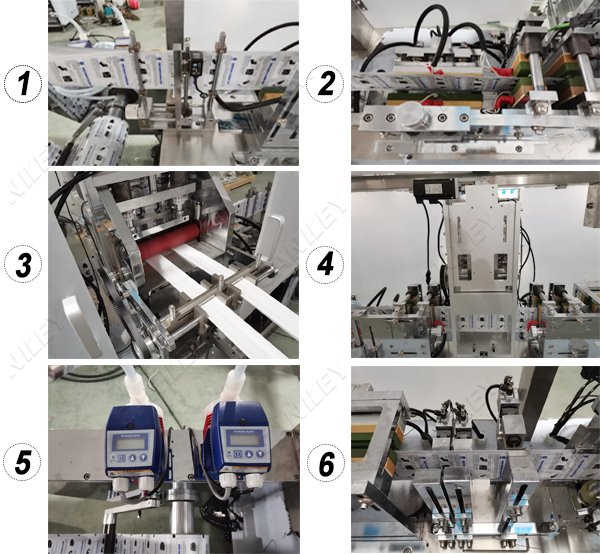

Disinfectant Wipes Machine Structure:

1. Metering pumps: Add the liquid to the package accurately.

2. Bag making: Adjust the bag making machine so that the width of the bag can meet the actual requirements.

3. Touch screen: Make the operation easier, flexible and fast.

4. Date printing: Used to print date code, batch number and other information according to customer requirements.

5. Shell: Made of stainless steel 304, making the machine cleaner and sanitary.

6. Cutter: Different cutter shapes can be changed according to customer requirements.

Disinfectant Wipes Manufacturing Process:

Non-woven folding-- add liquid-- cutting-- feeding into bag-- sealing --print date-- add easy to tear-- finished disinfectant wipes output

Disinfectant Wipes Machine Features:

O The machine has strong continuity and stability, and can work continuously for 24 hours.

O Using well-known brand metering pump, accurate control (dosing error is 0.01ml/time).

O Simple and easy to control, servo motor, PLC touch screen, temperature, speed and length of disinfectant wipes can be adjusted freely.

O The disinfectant wipes making machine added film release device, dust-free cover, hygienic and easy to clean.

O Round corner right angle no waste device, free switching, no waste, simple and fast

O The roller traction structure is adopted, and the operation is more stable.

O 90-degree automatic finished product output mechanism, making finished products smoother and more beautiful.

O Optical and electrical integration design, automatic fault alarm, safety control instructions.

Disinfectant Wipes Machine Structure:

1. Metering pumps: Add the liquid to the package accurately.

2. Bag making: Adjust the bag making machine so that the width of the bag can meet the actual requirements.

3. Touch screen: Make the operation easier, flexible and fast.

4. Date printing: Used to print date code, batch number and other information according to customer requirements.

5. Shell: Made of stainless steel 304, making the machine cleaner and sanitary.

6. Cutter: Different cutter shapes can be changed according to customer requirements.

Technical Data

| Model | CK-VPD250 |

| Packaging size | 50-110mm Length |

| Packaging material | Composite materials such as composite films, aluminized films, polyethylene / polypropylene |

| Wet wipes material | 30~80g/m2 Clean paper, wet strength paper, non-woven fabric, spunlace non-woven fabric |

| Unfold the size of the wet wipes |

Width:30-240mml Length:60-240mm(according to requirements) |

| Folding Method | Fold up to 8 times in the longitudinal direction and 4 times in the horizontal direction |

| Packaging speed | 60~120 bags/min |

| Dosing range | 0-5ml Liquid accuracy±0.01ML |

| Power | Single phase 220V 50/60Hz 4.8Kw |

| Gas consumption |

air compressor 0.5-0.8m3/min 300-500L/min |

| Machine weight | 1100Kg |

| Machine size |

2800mm×2800mm×1800mm |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price