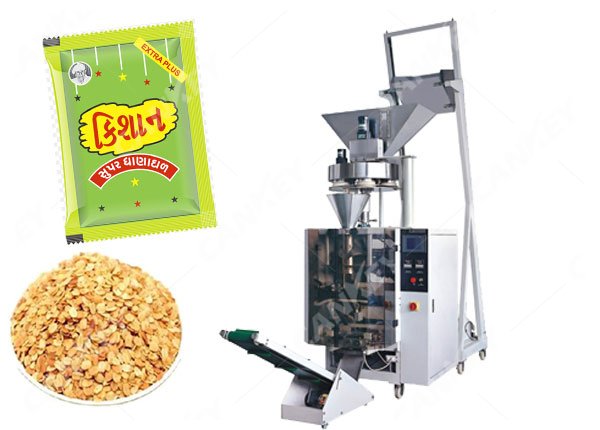

Vertical Form Fill Jelly Chocolate Beans Packing Machine

Features

Are you looking for a way to pack your jelly beans? We offer a wide range of packing machines providing numerous solutions for your jelly beans. This vertical form fill packing machine is one of them.

Jelly Beans Packing System Including:

Vibrating feeder, Z bucket conveyor, working platform, multi-head weigher, vertical filling and sealing machine, finished products conveyor, dropper metal detector.

Application:

The jelly chocolae packing machine is suitable for weighing granules products such as candies, seeds, jellies, chips, nuts, puffed food, biscuits, chocolate, pet food, frozen food, etc.

Jelly Beans Packing Machine Features:

☆Using intelligent temperature controller, temperature control is accurate; to ensure that the seal is beautiful and smooth.

☆Using PLC servo system, pneumatic control system, and large display touch screen constitute the drive control core; the packaging accuracy is maximized.

☆The touch screen can store the packaging parameters of 100 different products, and it does not need to be reset when the product is changed.

☆Equipped with a fault display system to help troubleshoot in time.

Jelly Bean Weighing Machine:

❤IP65 grade waterproof and dustproof design. All parts are made of stainless steel, which is clean and hygienic.

❤According to the characteristics of the products to be weighed, the opening and closing speed of the hopper door can be adjusted to prevent crushing and material jam.

❤Powerful data statistics function, record the total number of packages, qualified rate and single bag error of each batch.

❤With strong compatibility, it can be installed directly above the jelly chocolate packing machine and has a more compact structure.

❤Save a lot of raw material and labor costs, and return on investment quickly.

Z Bucket Conveyor:

1. Vertical lifting: 90-degree conveying, saving floor space and low power loss.

2. The material is carried by the hopper without scattering, and it can be matched with the packaging machine and the multi-head weigher to realize the material level tracking and automatic feeding.

Working Platform:

1. With safety bars and stairs, the platform is made of patterned aluminum or iron plate. 2. Beautiful, sturdy, non-slip countertop, practical and safe. Mainly made of 304 stainless steel or carbon steel material, clean and hygienic. It is mainly used for load-bearing combination weighing and is an important part of quantitative automatic jelly bean packaging system.

Finished Product Conveyor:

1. It adopts belt conveying, which can be used alone or matched with the packaging machine to complete the product conveying.

2. Can be designed according to the data provided by the customer or on-site survey, and provide a reasonable and economical overall solution.

Jelly Beans Packing System Including:

Vibrating feeder, Z bucket conveyor, working platform, multi-head weigher, vertical filling and sealing machine, finished products conveyor, dropper metal detector.

Application:

The jelly chocolae packing machine is suitable for weighing granules products such as candies, seeds, jellies, chips, nuts, puffed food, biscuits, chocolate, pet food, frozen food, etc.

Jelly Beans Packing Machine Features:

☆Using intelligent temperature controller, temperature control is accurate; to ensure that the seal is beautiful and smooth.

☆Using PLC servo system, pneumatic control system, and large display touch screen constitute the drive control core; the packaging accuracy is maximized.

☆The touch screen can store the packaging parameters of 100 different products, and it does not need to be reset when the product is changed.

☆Equipped with a fault display system to help troubleshoot in time.

Jelly Bean Weighing Machine:

❤IP65 grade waterproof and dustproof design. All parts are made of stainless steel, which is clean and hygienic.

❤According to the characteristics of the products to be weighed, the opening and closing speed of the hopper door can be adjusted to prevent crushing and material jam.

❤Powerful data statistics function, record the total number of packages, qualified rate and single bag error of each batch.

❤With strong compatibility, it can be installed directly above the jelly chocolate packing machine and has a more compact structure.

❤Save a lot of raw material and labor costs, and return on investment quickly.

Z Bucket Conveyor:

1. Vertical lifting: 90-degree conveying, saving floor space and low power loss.

2. The material is carried by the hopper without scattering, and it can be matched with the packaging machine and the multi-head weigher to realize the material level tracking and automatic feeding.

Working Platform:

1. With safety bars and stairs, the platform is made of patterned aluminum or iron plate. 2. Beautiful, sturdy, non-slip countertop, practical and safe. Mainly made of 304 stainless steel or carbon steel material, clean and hygienic. It is mainly used for load-bearing combination weighing and is an important part of quantitative automatic jelly bean packaging system.

Finished Product Conveyor:

1. It adopts belt conveying, which can be used alone or matched with the packaging machine to complete the product conveying.

2. Can be designed according to the data provided by the customer or on-site survey, and provide a reasonable and economical overall solution.

Technical Data

| Model | CK-LK420 |

| Film width | max 420mm |

| Bag width | 80-200mm |

| Bag length | 50-300mm |

| Packing speed | 15-80bags/min |

| Packing range | 150-1500ml |

| Film thickness | 0.04-0.10mm |

| Power | 2.5kw/220v 50-60Hz |

| Machine size | 1400*970*1700mm |

| Machine weight | 450kg |

| Air consumption | 0.4m³/min 0.6mpa |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price