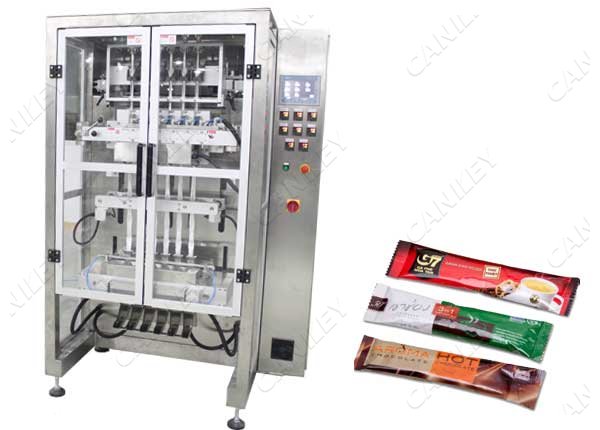

High Quality Multi Lane Powder Stick Packing Machine

Features

The multi lane powder packing machine is suitable for coffee powder, tea powder, sugar powder, etc.

Powder Stick Packing Machine Composition:

〇 PLC control system: user-friendly touch screen control interface, simple and quick parameter setting, with automatic fault alarm, automatic shutdown, automatic diagnosis functions.

〇 Temperature table: Horizontal and vertical sealing temperature are independently controlled, suitable for packaging of various materials.

〇 Screw metering method: the multi lane powder packing machine adopts the servo motor to control the screw filling method, the packaging accuracy is high, and it is easy to clean.

〇 Film pulling system: The servo-controlled horizontal sealing type pull-down film system ensures more accurate bag pulling.

〇 Automatic hob film separating device: Not easy to break, accurate separation.

〇 Hot-pressed mid-sealed area: Independent PID temperature control, vertical sealing adopts hot-seal form, suitable for multi-style bag packaging, stable forming and good sealing.

〇 End seal cutting area: constant temperature heat sealing cutter, sealing the front and back ends of the packaged product to avoid curling or loopholes in the sealing position.

Powder Stick Packing Machine Features:

* For powder materials, a long screw is specially configured for push-pull feeding, and each lane of bags can be accurately metered and adjusted.

* The multi lane powder packing machine can automatically control the sealing temperature, and the control accuracy can reach about ± 1C °. Adapt to a variety of packaging films produced at home and abroad.

* The powder stick packing machine using a combined sealing knife. Back seal, upper and lower horizontal seals are alternately sealed in multiple lanes. The seal is tight, the packaging is fast, and the bag shape is flat.

* The bag length can be adjusted quickly and conveniently without changing the mold.

Powder Stick Packing Machine Composition:

〇 PLC control system: user-friendly touch screen control interface, simple and quick parameter setting, with automatic fault alarm, automatic shutdown, automatic diagnosis functions.

〇 Temperature table: Horizontal and vertical sealing temperature are independently controlled, suitable for packaging of various materials.

〇 Screw metering method: the multi lane powder packing machine adopts the servo motor to control the screw filling method, the packaging accuracy is high, and it is easy to clean.

〇 Film pulling system: The servo-controlled horizontal sealing type pull-down film system ensures more accurate bag pulling.

〇 Automatic hob film separating device: Not easy to break, accurate separation.

〇 Hot-pressed mid-sealed area: Independent PID temperature control, vertical sealing adopts hot-seal form, suitable for multi-style bag packaging, stable forming and good sealing.

〇 End seal cutting area: constant temperature heat sealing cutter, sealing the front and back ends of the packaged product to avoid curling or loopholes in the sealing position.

Powder Stick Packing Machine Features:

* For powder materials, a long screw is specially configured for push-pull feeding, and each lane of bags can be accurately metered and adjusted.

* The multi lane powder packing machine can automatically control the sealing temperature, and the control accuracy can reach about ± 1C °. Adapt to a variety of packaging films produced at home and abroad.

* The powder stick packing machine using a combined sealing knife. Back seal, upper and lower horizontal seals are alternately sealed in multiple lanes. The seal is tight, the packaging is fast, and the bag shape is flat.

* The bag length can be adjusted quickly and conveniently without changing the mold.

Technical Data

| Package material thickness | 0.05-0.15 mm |

| Bag length range | 50mm-200mm |

| Bag width range | 20-45mm |

| Sealing width | 4-15mm (according to customer needs) |

| Packing speed | 20-40 bags/min |

| Gas source | 0.6-0.8Mpa |

| Power supply specification | 220V/380V 50/60HZ |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price