Small Scale Automatic Honey Filling Machine for Sale

Features

The honey filling machine can fill jars and bottles with consistent precision. And will not be affected by the consistency of honey.

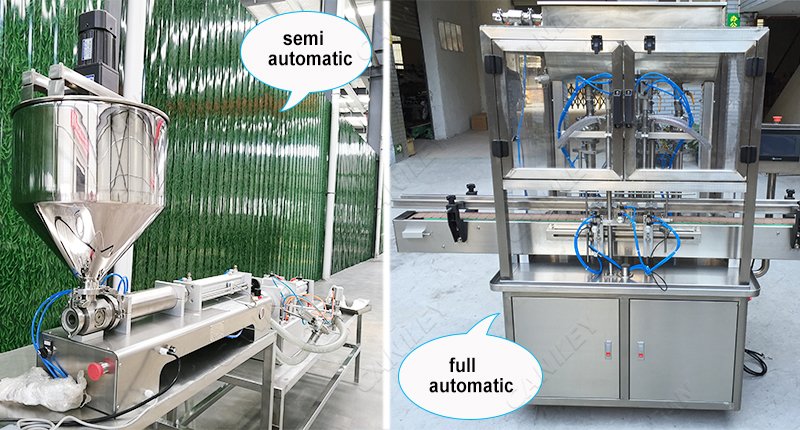

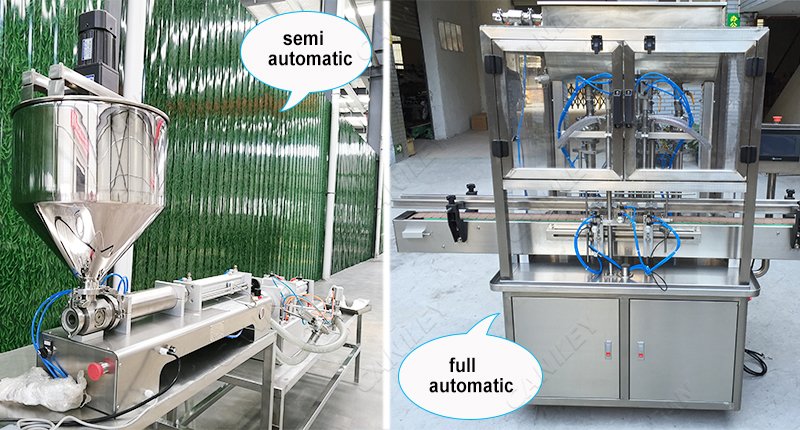

The configuration of the filling machine can be customized according to facility space requirements and applications, and semi-automatic(with single and double filling heads)and fully automatic(with 2-12 filling heads) models are available.

Application:

This automatic honey filling machine for sale can be used in many industries and products, such as honey, jam, cream, syrup, etc. It is ideal packaging equipment for filling honey into bottles or jars. The filling volume is from 100-1000ml, and the filling speed is 16-20 bottles/min. The actual filling speed is related to the filling head of the honey bottle filling machine.

〇 Seal is made of silicone rubber (wear, high temperature, acid and alkali, corrosion resistance), fluoro rubber (wear, strong acid and alkali, strong corrosion).

〇 All working procedures of the honey bottling machine are controlled by a PLC control system, making it easier to adjust the working status and filling steps of the machine.

〇The honey filling machine for sale design is reasonable, the structure is compact, the appearance is beautiful, the performance is stable, the filling precision is high, the operation is simple, and the maintenance is convenient.

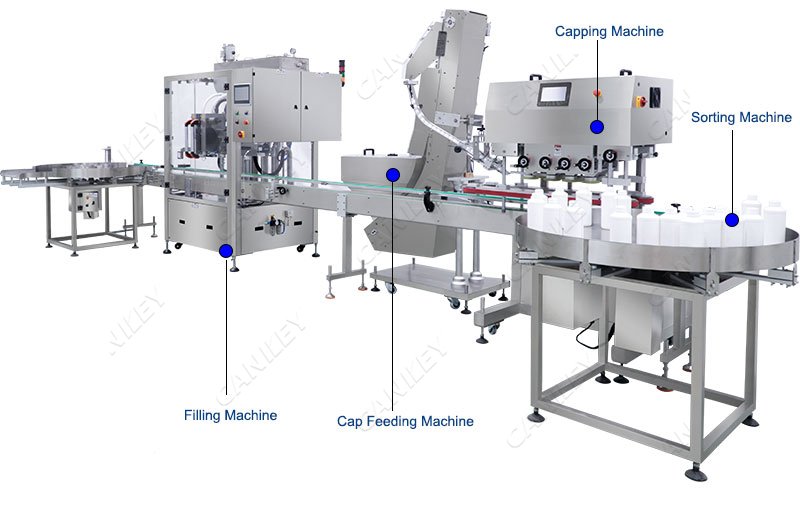

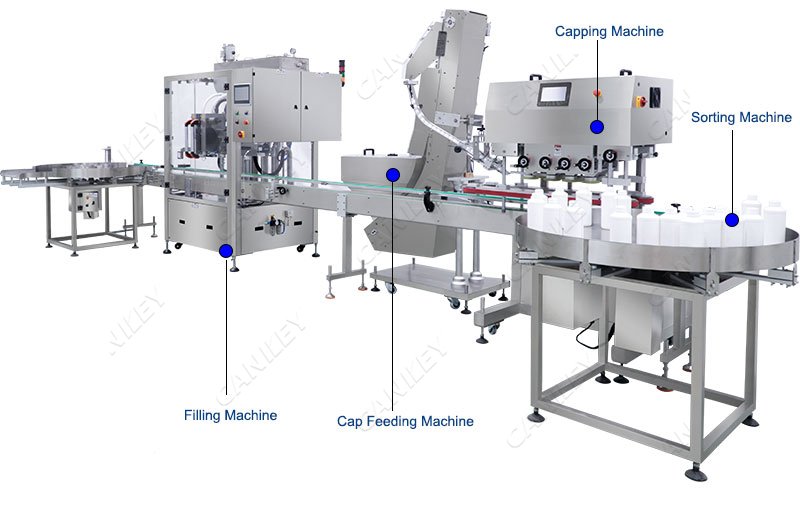

According to the packaging requirements and factory layout of different customers, we can provide semi-automatic to fully automatic honey packaging solutions. Usually includes capping machine, labeling machine, metal detection and other equipment.

Capping machine: This machine is mainly used for screw cap sealing of glass and PET bottles. The screw cap is a kind of packaging cover with reliable sealing and convenient opening. The material is generally aluminum alloy and plastic. It is screwed tightly under the action of the capping machine to achieve the sealing effect. Even long-term work can achieve stable and reliable results with consistent torque.

Labeling machine: Affix the label to the specified packaging container or product. The back of the label is self-contained with adhesive and is regularly arranged on the smooth backing paper, and the peeling mechanism on the labeling machine can automatically peel it off. Different types of labeling machines can complete single-sided, multi-sided, cylindrical and other types of labeling work.

Excellent quality: Our products are trusted by customers for their excellent quality and have passed ISO and CE certification.

Solution: Provide you with a highly compatible honey filling line, which can quickly switch varieties and specifications, and is equipped with a flexible stand-alone machine.

Personal service: We are aware of the complexity and diversity of customer needs. We know that sometimes, adjusting the scope of services to specific requirements may be the decisive factor. This is why we provide customers with the option of creating specialized services, tailoring services according to their needs. For example, capacity, packaging, configuration, etc.

The configuration of the filling machine can be customized according to facility space requirements and applications, and semi-automatic(with single and double filling heads)and fully automatic(with 2-12 filling heads) models are available.

Application:

This automatic honey filling machine for sale can be used in many industries and products, such as honey, jam, cream, syrup, etc. It is ideal packaging equipment for filling honey into bottles or jars. The filling volume is from 100-1000ml, and the filling speed is 16-20 bottles/min. The actual filling speed is related to the filling head of the honey bottle filling machine.

Honey Bottle Filling Machine Working Principle:

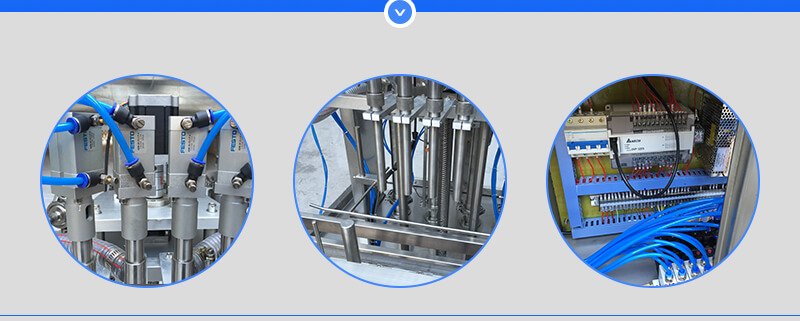

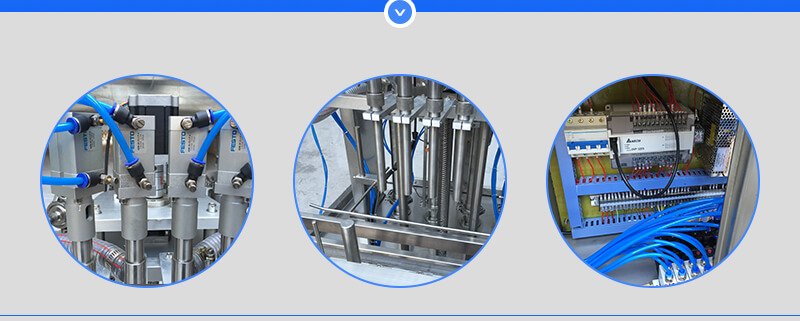

Reciprocating motion of the cylinder drives the piston to generate negative pressure and thrust in the piston cylinder, sucking in material and pushing material.Honey Filling Machine Features:

〇 The honey contact part is made of stainless steel, which can avoid product contamination. And the machine is easy to clean.〇 Seal is made of silicone rubber (wear, high temperature, acid and alkali, corrosion resistance), fluoro rubber (wear, strong acid and alkali, strong corrosion).

〇 All working procedures of the honey bottling machine are controlled by a PLC control system, making it easier to adjust the working status and filling steps of the machine.

〇The honey filling machine for sale design is reasonable, the structure is compact, the appearance is beautiful, the performance is stable, the filling precision is high, the operation is simple, and the maintenance is convenient.

Customized Honey Packing Solution:

According to the packaging requirements and factory layout of different customers, we can provide semi-automatic to fully automatic honey packaging solutions. Usually includes capping machine, labeling machine, metal detection and other equipment.Capping machine: This machine is mainly used for screw cap sealing of glass and PET bottles. The screw cap is a kind of packaging cover with reliable sealing and convenient opening. The material is generally aluminum alloy and plastic. It is screwed tightly under the action of the capping machine to achieve the sealing effect. Even long-term work can achieve stable and reliable results with consistent torque.

Labeling machine: Affix the label to the specified packaging container or product. The back of the label is self-contained with adhesive and is regularly arranged on the smooth backing paper, and the peeling mechanism on the labeling machine can automatically peel it off. Different types of labeling machines can complete single-sided, multi-sided, cylindrical and other types of labeling work.

Why Choose Our Honey Bottle Filling Machine?

Service promise: Accept your consultation before sales, organize special technical seminars, and discuss your equipment requirements. Provide you with a detailed "equipment proposal".Excellent quality: Our products are trusted by customers for their excellent quality and have passed ISO and CE certification.

Solution: Provide you with a highly compatible honey filling line, which can quickly switch varieties and specifications, and is equipped with a flexible stand-alone machine.

Personal service: We are aware of the complexity and diversity of customer needs. We know that sometimes, adjusting the scope of services to specific requirements may be the decisive factor. This is why we provide customers with the option of creating specialized services, tailoring services according to their needs. For example, capacity, packaging, configuration, etc.

Technical Data

| Model | CK-GT4T-4G |

| Voltage | 220V 50/60Hz |

| Air Pressure | 0.5-0.7Mpa |

| SS Material | SUS304 |

| Pistion Material | PTFE |

| Main Cylinder | SMC(Japan) |

| PLC&Screen | Delta |

| Filling Volume Range | 100-1000ml |

| Filling Heads | 4 |

| Filling Speed | 16-20 Bottles/Min |

| Machine Size (L*W* H) | 2000*1050*1900 mm |

| Weight | 350Kg |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price