Auger Filler Curry Powder/Cinnamon Powder Packing Machine

Features

There are different types of cinnamon powder packing machine for different packing purpose. But they all use the auger filler principle. And widely used to all kinds of spice powder or mixed spice powder packing. Such as: chili powder, curry powder, ginger powder, turmeric powder, garlic powder, etc.

This machine is used to fill cinnamon powder & curry powder into bottles. According to the requirements of packaging capacity, you can choose 1, 2, 3, 4 filling heads, etc.

O The cinnamon powder packing machine uses a auger filler for filling, servo, indexing disc positioning system, touch screen display, PLC control, and packaging accuracy and speed are improved.

O Using touch screen display, the screen displays English (multiple languages can be customized) working status and operating instructions, which is simple and intuitive. The cinnamon powder packaging weight is steplessly adjustable, the operation mode can be changed arbitrarily, and the fault alarm prompts.

O The filling is driven by servo, with high positioning accuracy, large torque, long life, and adjustable speed.

O Replacing the screw attachment can be adapted to the packaging of large particles to ultra-fine powder materials. According to different materials, vacuum suction, vibration and other devices can be added.

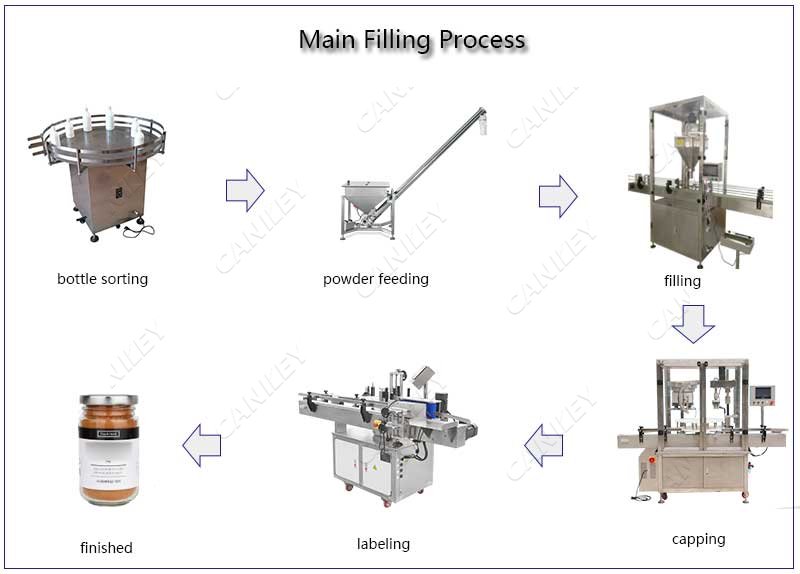

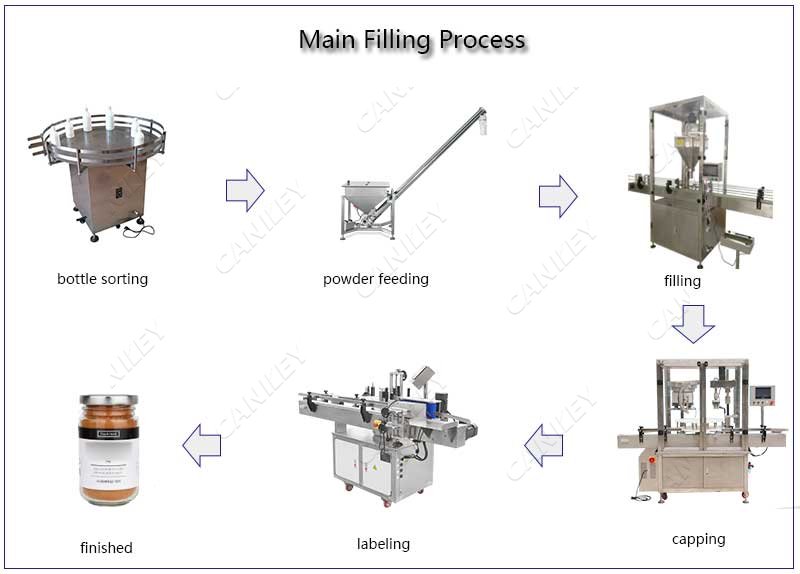

This cinnamon powder packing machine can be used in conjunction with other equipment to form an automatic cinnamon powder filling line:

Soring bottle→The screw feeder feeds the cinnamon powder to the metering machine→Measuring→Filling cinnamon powder→Capping→Output

2. Pouch packing

This curry powder packing machine is used to pack cinnamon powder and curry powder into bags. According to the requirements of the packaging bag, you can choose a vertical packing machine or premade pouch packing machine to complete the packaging process.

A: Vertical packing machine:

O The curry powder packing machine can automatically complete bag making, metering, blanking, sealing, and slitting. At the same time, it can be configured to print batch numbers and other functions according to customer requirements.

O The advanced microcomputer controller drives the stepping motor to control the bag length, with stable performance, convenient adjustment and accurate detection.

O Stepless speed regulation, and different unloading mechanisms can be configured to pack curry powder and other products.

O Packaging film: Polypropylene/polyethylene, aluminum foil/polyethylene, polyester/aluminized/polyethylene, nylon/reinforced polyethylene, paper/polyethylene, tea filter paper, etc.

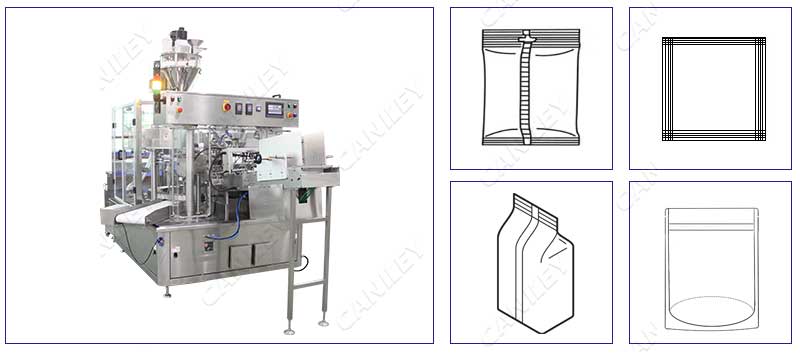

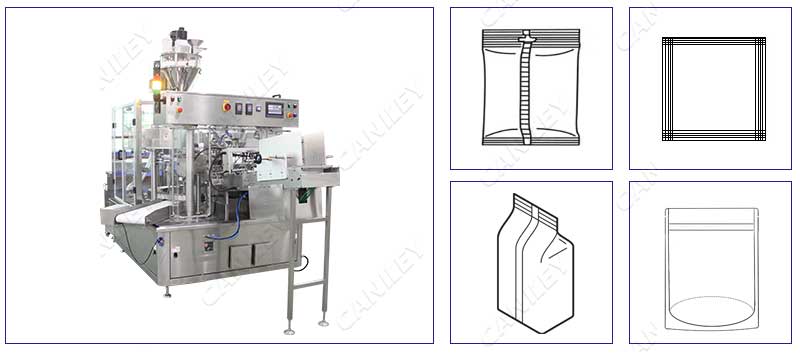

B: Premade pouch packing machine:

☆ Horizontal bag delivery method: More packaging bags can be stored, the quality of the bag is lower, and the bag splitting and bag loading rate is high.

☆ Screw feeder: The moving screw of the filling motor has the advantages of accurate positioning, high precision, fast speed, large torque, long life, settable speed, and good stability.

☆ Metering device: The device is driven by a high-precision stepping motor, and the screw is filled. In the measuring range of the machine, different measuring ranges can be completed by several screws of different sizes. The operation is simple, convenient and precise.

☆ Curry powder does not leak out, and the outlet is filled with dust suction device to protect the workshop environment.

☆ This curry powder packing machine can be used in a variety of bag types, such as stand up pouch, flat bags, zipper bags, four-side sealing bags, three-side sealing bags, paper bags, etc.

Types of Cinnamon Powder Packing Machine:

1. Bottle fillingThis machine is used to fill cinnamon powder & curry powder into bottles. According to the requirements of packaging capacity, you can choose 1, 2, 3, 4 filling heads, etc.

O The cinnamon powder packing machine uses a auger filler for filling, servo, indexing disc positioning system, touch screen display, PLC control, and packaging accuracy and speed are improved.

O Using touch screen display, the screen displays English (multiple languages can be customized) working status and operating instructions, which is simple and intuitive. The cinnamon powder packaging weight is steplessly adjustable, the operation mode can be changed arbitrarily, and the fault alarm prompts.

O The filling is driven by servo, with high positioning accuracy, large torque, long life, and adjustable speed.

O Replacing the screw attachment can be adapted to the packaging of large particles to ultra-fine powder materials. According to different materials, vacuum suction, vibration and other devices can be added.

This cinnamon powder packing machine can be used in conjunction with other equipment to form an automatic cinnamon powder filling line:

Soring bottle→The screw feeder feeds the cinnamon powder to the metering machine→Measuring→Filling cinnamon powder→Capping→Output

2. Pouch packing

This curry powder packing machine is used to pack cinnamon powder and curry powder into bags. According to the requirements of the packaging bag, you can choose a vertical packing machine or premade pouch packing machine to complete the packaging process.

A: Vertical packing machine:

O The curry powder packing machine can automatically complete bag making, metering, blanking, sealing, and slitting. At the same time, it can be configured to print batch numbers and other functions according to customer requirements.

O The advanced microcomputer controller drives the stepping motor to control the bag length, with stable performance, convenient adjustment and accurate detection.

O Stepless speed regulation, and different unloading mechanisms can be configured to pack curry powder and other products.

O Packaging film: Polypropylene/polyethylene, aluminum foil/polyethylene, polyester/aluminized/polyethylene, nylon/reinforced polyethylene, paper/polyethylene, tea filter paper, etc.

B: Premade pouch packing machine:

☆ Horizontal bag delivery method: More packaging bags can be stored, the quality of the bag is lower, and the bag splitting and bag loading rate is high.

☆ Screw feeder: The moving screw of the filling motor has the advantages of accurate positioning, high precision, fast speed, large torque, long life, settable speed, and good stability.

☆ Metering device: The device is driven by a high-precision stepping motor, and the screw is filled. In the measuring range of the machine, different measuring ranges can be completed by several screws of different sizes. The operation is simple, convenient and precise.

☆ Curry powder does not leak out, and the outlet is filled with dust suction device to protect the workshop environment.

☆ This curry powder packing machine can be used in a variety of bag types, such as stand up pouch, flat bags, zipper bags, four-side sealing bags, three-side sealing bags, paper bags, etc.

Technical Data

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price