Meal Replacement Powder Filling Packing Machine

Features

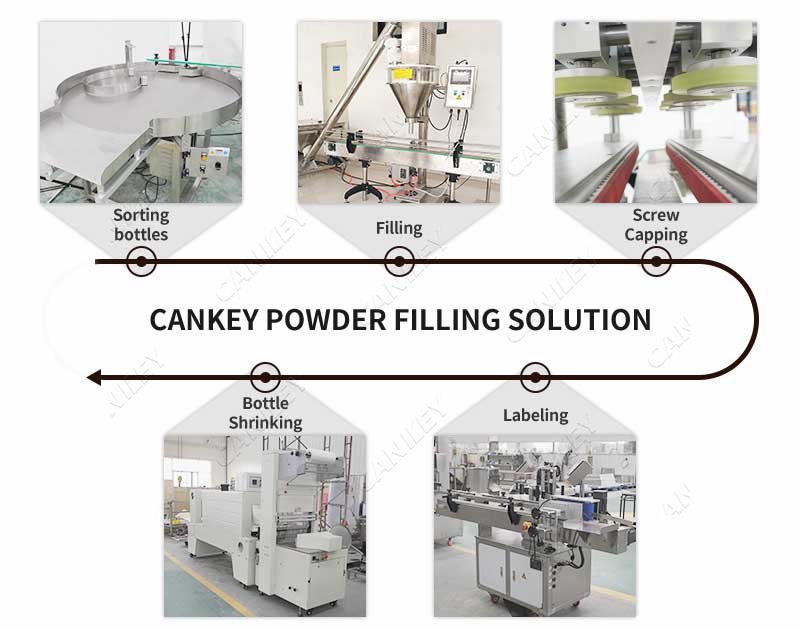

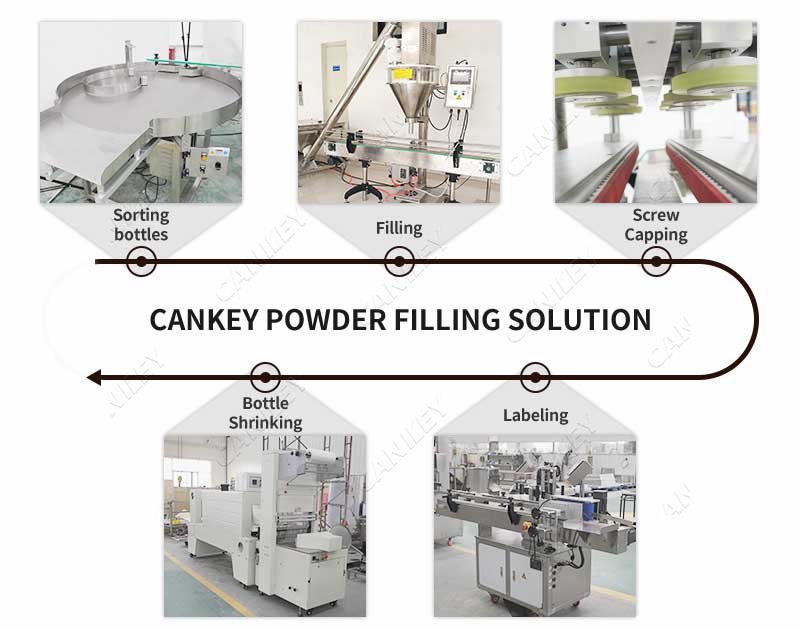

This meal replacement powder filling machine is specially designed for filling powders into bottles. It can be combined with bottle unscrambler, capping machine, electromagnetic induction aluminum foil sealing machine, labeling machine, case sealing machine and other equipment to form a fully automatic powder filling line. Ensure the hygiene of the packaging environment and reduce dust leakage.

Meal Replacement Powder Filling Machine Application:

This machine is widely used in the whole process of quantitative filling, cap feeding, capping, sealing, labeling and packaging of products in the pharmaceutical, food, health care, chemical and other industries.

Meal Replacement Powder Filling Machine Featrues:

# In line with national GMP standards and food hygiene certification, the whole machine is made of stainless steel (316L material can be customized).

# Fully sealed glass and stainless steel combined semi-open material box, which can be easily disassembled and washed without tools.

# The meal replacement packing machine adopts intelligent touch screen, PLC control, stable work, anti-interference, convenient operation, intuitive, long life and so on.

# The filling adopts servo motor to drive the screw, which has the advantages of accurate positioning, high precision, fast speed, large torque, adjustable speed and good stability.

# The screw attachment adopts quick-clamp connection, which can be replaced quickly and can meet the packaging requirements of various materials.

# The chain conveyor belt transports the bottles, the turntable allocates and positions, and automatically completes the work of pre-filling, supplementary filling, weighing and cyclic complementation.

Because there are many types of meal replacements, in addition to powders, there are also bars and drinks. Different forms of meal replacements require different packaging equipment to complete the packing process.

For meal replacement bar:

This is a product in solid form, usually in a single package for easy portability. Pillow type packing machines are very suitable for the packaging of the meal replacements bar. The packaging process is very simple. The meal replacement is placed in the feeder, and the conveyor belt automatically transports the meal replacement to the packaging position, where it is packaged in film. Then, after heating, it is pressed into shape, and sent to the cross-sealing cutter for heat-sealing and cross-sealing, and then cut off. The finished product is output by the conveyor belt.

For meal replacement drinks:

For liquid meal replacements, spout pouch or zipper pouch is usually used for convenience of consumption and preservation. The premade pouch packing machine can do the job well. Realize the work tasks of the whole process of meal replacement from feeding, measuring, sealing, embossing and packaging. No waste of meal replacement.

According to the type of meal replacement and the packaging requirements of customers, we can customize suitable packaging solutions.

Meal Replacement Powder Filling Machine Application:

This machine is widely used in the whole process of quantitative filling, cap feeding, capping, sealing, labeling and packaging of products in the pharmaceutical, food, health care, chemical and other industries.

Meal Replacement Powder Filling Machine Featrues:

# In line with national GMP standards and food hygiene certification, the whole machine is made of stainless steel (316L material can be customized).

# Fully sealed glass and stainless steel combined semi-open material box, which can be easily disassembled and washed without tools.

# The meal replacement packing machine adopts intelligent touch screen, PLC control, stable work, anti-interference, convenient operation, intuitive, long life and so on.

# The filling adopts servo motor to drive the screw, which has the advantages of accurate positioning, high precision, fast speed, large torque, adjustable speed and good stability.

# The screw attachment adopts quick-clamp connection, which can be replaced quickly and can meet the packaging requirements of various materials.

# The chain conveyor belt transports the bottles, the turntable allocates and positions, and automatically completes the work of pre-filling, supplementary filling, weighing and cyclic complementation.

Because there are many types of meal replacements, in addition to powders, there are also bars and drinks. Different forms of meal replacements require different packaging equipment to complete the packing process.

For meal replacement bar:

This is a product in solid form, usually in a single package for easy portability. Pillow type packing machines are very suitable for the packaging of the meal replacements bar. The packaging process is very simple. The meal replacement is placed in the feeder, and the conveyor belt automatically transports the meal replacement to the packaging position, where it is packaged in film. Then, after heating, it is pressed into shape, and sent to the cross-sealing cutter for heat-sealing and cross-sealing, and then cut off. The finished product is output by the conveyor belt.

For meal replacement drinks:

For liquid meal replacements, spout pouch or zipper pouch is usually used for convenience of consumption and preservation. The premade pouch packing machine can do the job well. Realize the work tasks of the whole process of meal replacement from feeding, measuring, sealing, embossing and packaging. No waste of meal replacement.

According to the type of meal replacement and the packaging requirements of customers, we can customize suitable packaging solutions.

Technical Data

| Model | CK-1 |

| Packing weight | 5-5000g (the screw attachment needs to be replaced) |

| packing accuracy | <±1% |

| Packing speed | 20-35bags/min (Detailed packing speed depends on manual, packaging materials) |

| Voltage | 3P/380V 50-60Hz |

| Power | 1.2kw |

| Weight | 220kg |

| Size | 750×600×1850mm |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price