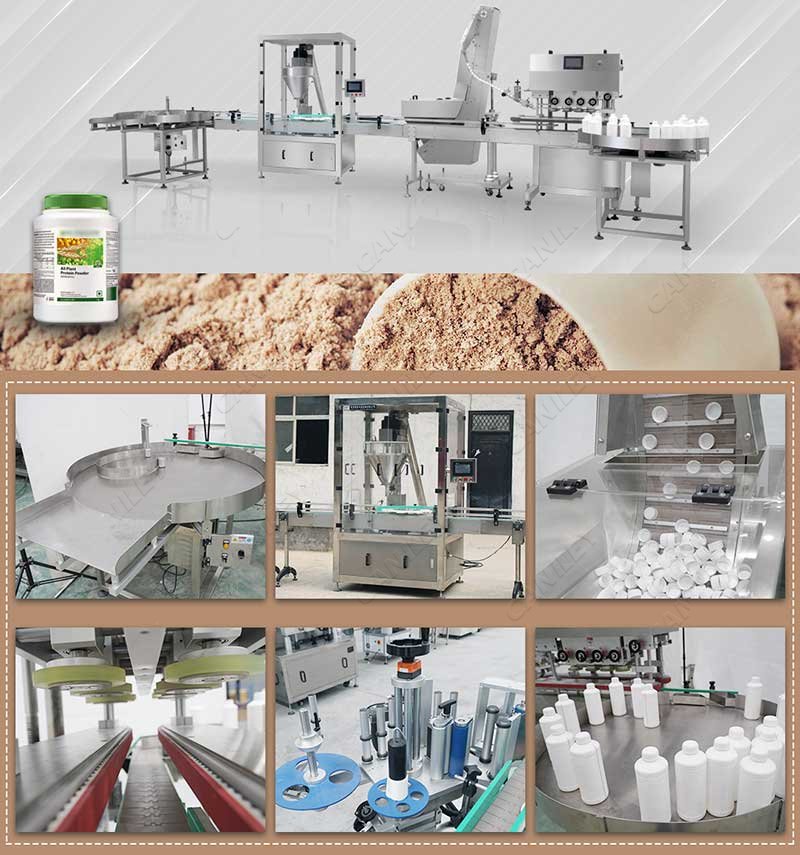

Simple Operation Protein Powder Filling Machine

Features

The protein powder filling machine reasonably uses a fully automatic production process and a auger filling structure. On the basis of introducing and absorbing foreign advanced technology, a bottle filling is independently developed by our company. High-precision enclosed cam indexing station with high precision, reliable operation and long service life.

Electronic touch screen: The whole machine adopts electronic display touch screen control, adopts PLC intelligent program design and touch screen manual operation control system. When setting parameters, it is convenient to adjust with one key, which is simple and fast. In addition, it also has the function of alarming and displaying faults, and monitoring the operation of the machine at any time.

Conveyor belt: Used to place protein powder bottle, the conveyor belt can be customized according to the size of the bottle, with adjustable railings on both sides, and the gap at both ends can be adjusted.

Auger metering device: The protein powder is measured by auger. It adopts servo motor to control the screw, which has the advantages of high precision and stable performance. And the hopper is made of 304 stainless steel. It can effectively avoid protein powder contamination.

# Adopt PLC intelligent program design and touch screen manual operation control system.

# The volume quantification of the single-head screw, the overall appearance material is mainly made of 304 stainless steel.

# Transparent material box that opens horizontally, can be disassembled and cleaned without tools for easy cleaning.

# Equipped with a dust removal device, connected with the negative pressure pipeline, it can effectively absorb dust during the filling process and effectively protect the workshop environment.

# Added stopper detection for bottle volume, including stopper pause function, easy-to-connect automatic filling lines, and smooth control.

# The contact material parts are made of stainless steel, and the motors, cylinders, electrical accessories, pneumatic components, etc. are all selected from well-known brands, and can also be designated by customers.

Application:

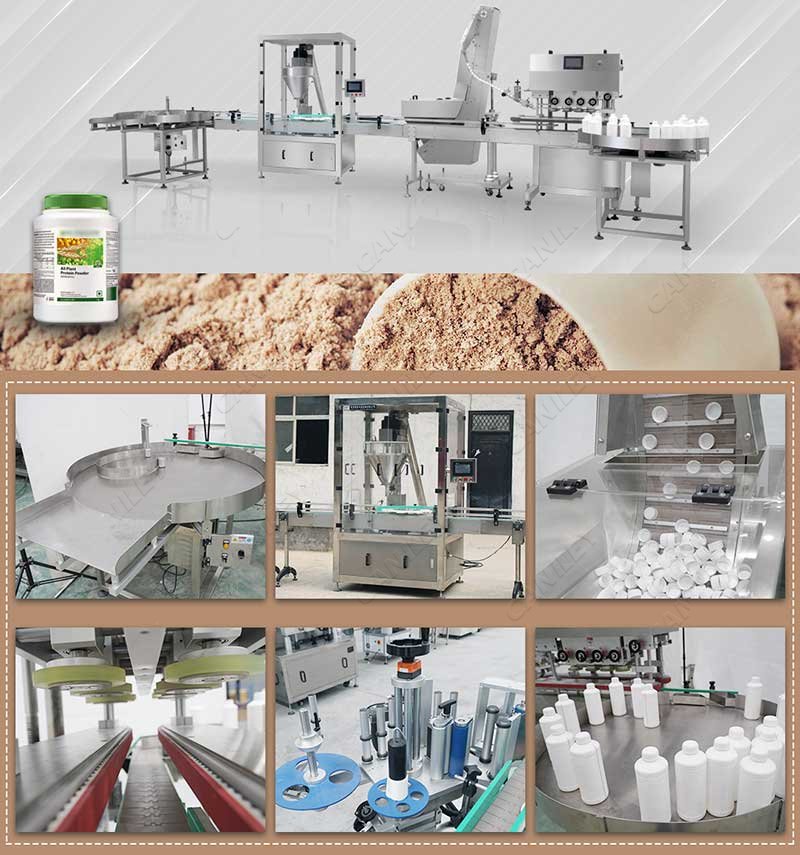

As a powder filling machine manufacturer, the machines we produce are widely used in food, medicine, daily necessities and other industries to fill powdery materials. Such as powdered materials such as milk powder, protein powder, cocoa powder, coffee powder, rice flour, etc.

For customers who want to achieve mass production, we also offer automatic powder filling lines.

Protein Powder Filling Machine Structure:

Filling device: The filling device is equipped with a dust removal device, which is connected to the negative pressure pipeline, which can effectively absorb dust during the filling process and effectively protect the workshop environment.Electronic touch screen: The whole machine adopts electronic display touch screen control, adopts PLC intelligent program design and touch screen manual operation control system. When setting parameters, it is convenient to adjust with one key, which is simple and fast. In addition, it also has the function of alarming and displaying faults, and monitoring the operation of the machine at any time.

Conveyor belt: Used to place protein powder bottle, the conveyor belt can be customized according to the size of the bottle, with adjustable railings on both sides, and the gap at both ends can be adjusted.

Auger metering device: The protein powder is measured by auger. It adopts servo motor to control the screw, which has the advantages of high precision and stable performance. And the hopper is made of 304 stainless steel. It can effectively avoid protein powder contamination.

Protein Powder Filling Machine Features:

# Adopt PLC intelligent program design and touch screen manual operation control system.# The volume quantification of the single-head screw, the overall appearance material is mainly made of 304 stainless steel.

# Transparent material box that opens horizontally, can be disassembled and cleaned without tools for easy cleaning.

# Equipped with a dust removal device, connected with the negative pressure pipeline, it can effectively absorb dust during the filling process and effectively protect the workshop environment.

# Added stopper detection for bottle volume, including stopper pause function, easy-to-connect automatic filling lines, and smooth control.

# The contact material parts are made of stainless steel, and the motors, cylinders, electrical accessories, pneumatic components, etc. are all selected from well-known brands, and can also be designated by customers.

Application:

As a powder filling machine manufacturer, the machines we produce are widely used in food, medicine, daily necessities and other industries to fill powdery materials. Such as powdered materials such as milk powder, protein powder, cocoa powder, coffee powder, rice flour, etc.

For customers who want to achieve mass production, we also offer automatic powder filling lines.

Technical Data

| Model | CK-1 |

| Packing weight | 5-5000g (the screw attachment needs to be replaced) |

| packing accuracy | <±1% |

| Packing speed | 20-35bags/min (Detailed packing speed depends on manual, packaging materials) |

| Voltage | 3P/380V 50-60Hz |

| Power | 1.2kw |

| Weight | 220kg |

| Size | 750×600×1850mm |

0086-15515573212

0086-15515573212 info@cankeytech.com

info@cankeytech.com

Chat Online

Chat Online Get Price

Get Price